General

Process BGA

Handling StencilQuik™

Method EZReball™

Method High Volume

Method Dry

Packaging Ceramic

Package Reballing Challenges

Optional

Services

The reballing of BGAs come with some challenges and therefore should not be attempted by inexperienced users unless properly trained-especially in the case of sensitive devices, expensive components or very high ball count components. BEST is knowledgeable in IEC TS 62647-4 standards for the restoration of BGAs, In addition cleanliness standard testing, ball shear testing, co-planarity testing and XRF testing are services BEST can perform post BGA reballing.

Popcorned BGA

Popcorned BGA

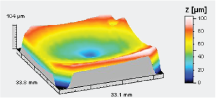

Profile of Warped BGA

Profile of Warped BGA