BGA Reballing Services

Rework / Repair Services

THE INDUSTRY'S BEST REBALLING SOLUTION

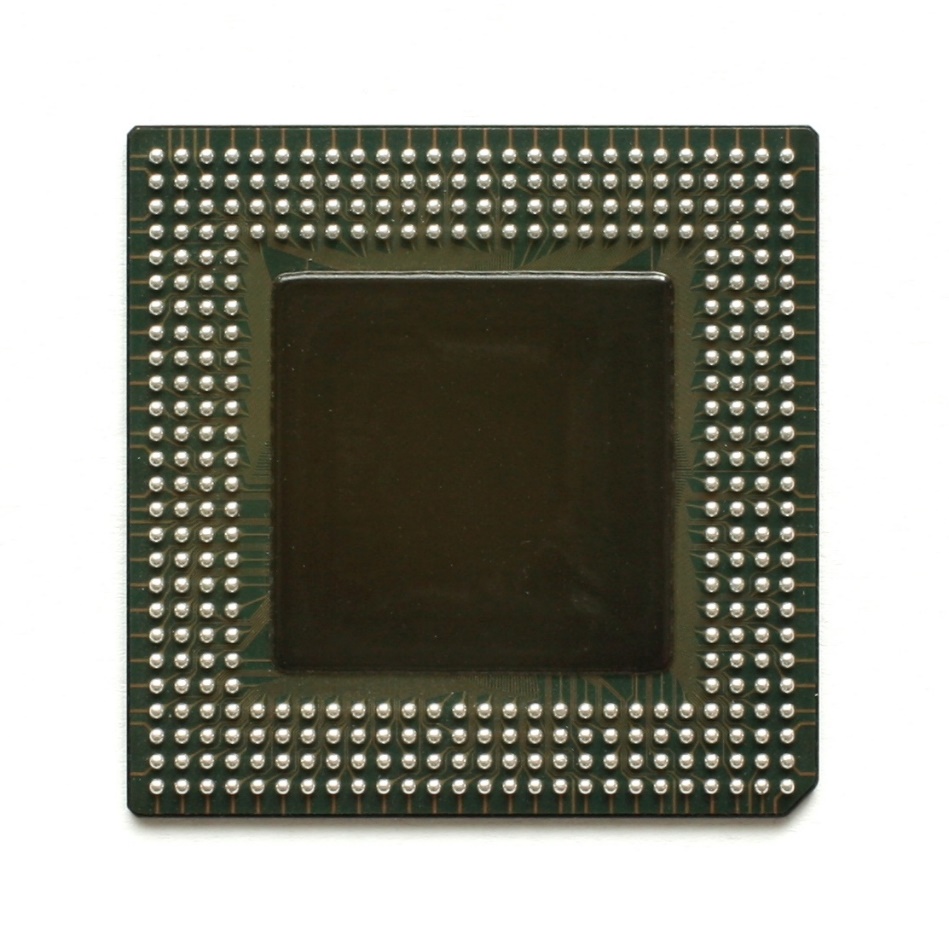

The reballing of a BGA returns BGAs to their original specifications and/or changes out the solder balls for a different alloy. BEST has the capabilities to handle a wide array of today's BGA package sizes and ball counts when it comes to solder reballing services. We utilize several highly reliable, repeatable, industry-wide proven solder deballing and reballing processes in compliance with industry specifications particular to the end use operating environment.

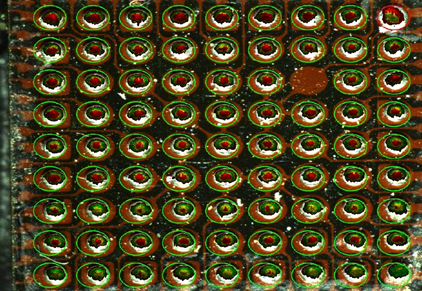

BEST Insures Reballed Devices Meet Industry Standards Using Automated Inspection

In addition, BEST has the capacity and flexibility to deal with both small and large BGA reballing production volumes – according to your specific requirements. Our extensive experience with device testing and specification review/writing gives our engineers the expertise to consult with you on BGA reballing processes and/or process specifications.

BEST BGA Reballed Device Take on a Variety of Patterns and Sizes

Our tight quality control standards and experience in dealing with all kinds of BGAs-from very large, high IO count military grade hardware costing thousands down to the 6 mil 0.4mm pitch newest devices. BEST has rigid MSD controls in place that help assure you that your device is being treated with greatest of care during the solder reballing BGA process at BEST Inc. We manage our EOS/ESD program based on the industry accepted EOS/ESD 2020 guidelines. Finally, for larger lot sizes or if specified by contract, BEST will use automated optical inspection to make sure the ball diameter is in spec, there is no large FOD present, there are no shorts or missing balls and will make sure the coplanarity of the solder balls are within specification. With these processes in place, the BGA reballing services we perform for you are to the highest standards.

AUTOMATED OPTICAL INSPECTION OF BGAs AFTER REBALLING

We can review your solder BGA reballing and other associated processing requirements, including cleanliness, testing, MSD Handling, reflow profile development and/or acceptance criteria development. We, are also able to review your testing requirements for cleanliness and ball shear as well as acoustic microscopy testing. If you need to have the components marked after reballing or put back onto tape and reel, we can provide the turnkey solution. Recently, a large medical device OEM came to BEST for guidance and advice on a BGA reballing process specification. The component manufacturer had discontinued the device in a given alloy. We consulted the OEM industry solder BGA reballing requirements and inspection standards (there are no formal ones). The OEM processed several lots comparing the reliability testing of both reballed and original devices in order to verify and qualify the process.

This manufacturer, who had never been involved in BGA reballing came to BEST looking for technical guidance. We were able to work with them and consult with them on a BGA reballing process definition, qualification for manufacturing and assist with developing a repeatable process for their critical application.

The bottom line is this, even if you don't know the first thing about BGA solder reballing, BEST can help! Our experts can assist you the same way we assisted our medical device OEM client – developing a solution that saves you time and money and meets your specifications.

We perform thousands of reballs every month from lot sizes from 1 to tens of thousands. Our experience, processes and knowledge is deep and wide when it comes to BGA reballing. We developed a unique BGA reballing preform, designing and fabricating them for worldwide customer usage. Several leading semiconductor device manufacturers use BEST EZReball™ preforms to reball their own devices.

BEST pick and place machinery for automated ball placement and flux dispense

Prior to sending the device required to be reballed in for processing we ask you to read our instructions for prepping the BGAs to be reballed in prior to shipment.

BEST Reballing Specifications

Package Sizes: 3 x 3mm to 60 x 60mm, ball count 4 to >8,000

Pitch: 0.3mm to 1.5mm

Ball sizes: 6 mils (150um) to 40 mils (1016 um)

Alloys: Sn63Pb37, SAC305, Sn90Pb10 (standard), other alloys, plastic core or solder-coated balls capable

Package Materials: Plastic, ceramic, metal

Conversions: Placing balls on bottom-terminated components (QFN, LGA)

Packaging: Tape and reel, tray

Deballing Methods: For low volumes-solder braid/wick or solder fountain

For non-contact automated vacuum solder excavation

Ball Attach Methods: For low volumes-EZReball™ reballing preforms-designed and manufactured in house

For high volumes-Automated pick and ball place system inclusive of flux dispense

Inspection:Low volume manual or X-Ray inspection for shorts, bridges, ball sphericity, ball diameter

Medium/High Volume: Automated inspection of ball diameter, ball coplanarity, shorts, missing, ball diameter, FOD

Other Services: Dry Packing, Baking, XRF testing, ion chromatography/cleanliness, automated optical inspection and coplanarity confirmation, solderability testing, laser marking, paint dot marking of various colors

Post reball verification and inspection services include shear testing, XRF alloy verification, visual inspection to confirm sphere condition, ball alignment, size and location,

Other available testing services include: Ball shear testing per JESD22-B117, Hermeticity testing (fine and gross leak) per MIL-STD-883, Destructive physical analysis (DPA) per MIL-STD-1580, SAM (scanning acoustic microscopy) testing per J-STD-035

Compliance RoHS, REACH, ITAR

Industry Standards:

| ISO 9001 | GEIA-0006 |

| J-STD-001 | NASA -STD-8739.2 |

| IPC 7721 | IEC TS62647-4. |

ESD: Per EOS/ESD 2020 guidelines

MSD: Per J-STD-033 guidelines

Typical lead times: 2-3 weeks for medium volume w/scheduled deliveries for greater quantities

Small quantities expedited delivery of 3-5 days

Why BEST BGA Reballing Services?

The flexibility in processes you may require, our wide degree of experience as well as our in house tooling for faster delivery make BEST your resource for BGA reballing services.