PCB Laser Depanelization

Laser Depaneling

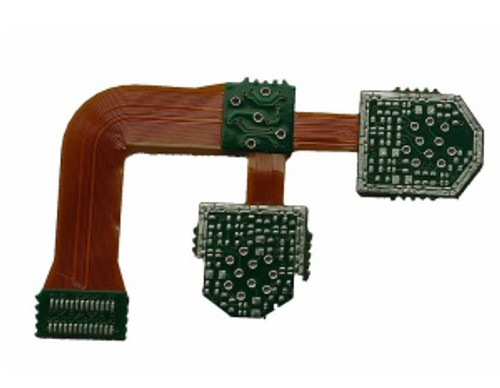

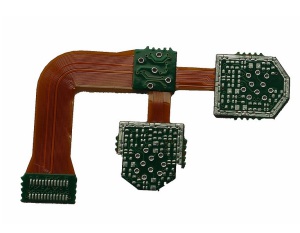

BEST Inc. provides laser depaneling services for printed circuit board manufacturers as well as EMS and OEMs. BEST’s numerous lasers are equipped to handle volumes from small prototype to large production runs. Laser depaneling can cut through plastics, ceramics and metals or some combination thereof. It is the right method to use when there are sharp corners or many tight radii of curvature in the PCB or in the flex circuit.

Depending on the material and the part requirements, BEST laser services provides a tool-less part removal process in the form of final perforation, scoring and hold-in tabs. Using a laser to perform the depaneling gives the user the advantage of speed and positional accuracy. Unlike mechanical methods there is no part induced stresses, no tooling cost and no cutting oils or other contaminants.

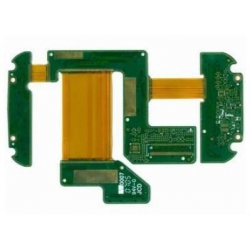

BEST laser depaneling is ideal for rigid-flex boards as it provides a precise way to cut through a variety of materials including but not limited to the following most common materials seen:

- FR4 multilayer,

- Flexible circuit boards,

- Flex-rigid circuit boards,

- Ceramics,

- RF materials (Rogers®, Teflon®),

- Combinations thereof, suitable for thicknesses of rigid flex laser depanelization

In addition, BEST can be that provider of laser depanelization when you have a lot of IoT devices which need to be precisely machined or cut out to fit perfectly into small mechanical enclosures.

In addition, BEST can be that provider of laser depanelization when you have a lot of IoT devices which need to be precisely machined or cut out to fit perfectly into small mechanical enclosures.

Because of the contact-free processing that goes on with laser depanelization of printed circuit boards, there is little distortion even when thin materials are used. When boards are milled or punched out using a mechanical tool there may prove to be a loss precision and potentially a distortion in the outside board dimensions. Worse yet it may crack solder joints when using these mechanical means. In BEST laser depanelization system feature fiducial registration and online scaling, which means already existing distortions can be compensated and the cut contours positioned precisely within the layout.

Perforations

Similar to scoring or v-grooves, laser perforations are another option for singulated board removal from a panel or sheet. Perforations can be laser formed to any size and spacing to meet the desired removal and securement forces.

Scoring

Laser scoring can produce a limited depth ablation line in the panelized boards. Generally speaking the depth of the score line is 50% of the material thickness and can be controlled to a desired depth. The scoring acts in a manner similar to the hold-tab to secure the part in the panel or sheet, but allows for individual parts to be ‘snapped’ out after processing. Laser scoring lines can also be used as a deliberate path for crack propagation or stress relief. When performing the score lines as a service BEST can either use the IPC guidelines or follow customer requirements.

Hold-in Tabs

Hold-in tabs are small uncut sections around the board which are used to secure the PCB in the panel. The hold-in tabs are used for ease of handling small boards or for printed circuit board securement for additional processing. The hold-in tab width is chosen based on the amount of force desired to remove the part from the panel/sheet or known forces to be applied by downstream processes like component loading. BEST laser services can create tabs in most board materials and to nearly any width and location about the part.

See more on laser depaneling technology at BEST’s article here.