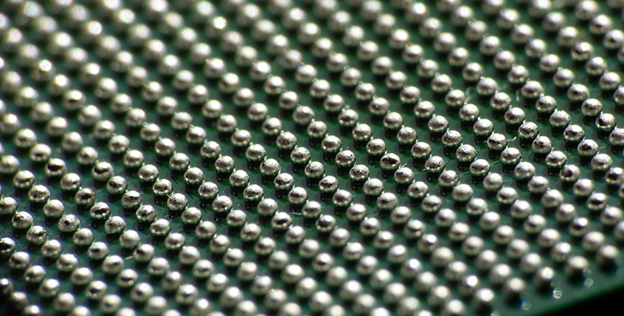

The following describes the general methodologies used by BEST for reattaching solder balls to either BGAs or CSPs as part of its BGA rework services. The three methodologies described herein are used by BEST Inc in the reattachment of solder balls to a variety of area array devices.

There are a variety of reasons new solder balls need to be attached to area array devices such as BGAs (ball grid arrays), sockets, CSPs (chip scale packages) and WLPs (wafer level packages). In some instances the device under consideration has been removed from a PCB and the component needs to be reballed prior to its re-use. Similarly when a device is removed from a PCB and it is the suspected failure it will need to be reballed in order to be electrically tested. Some components will need to have new solder balls put on to them due to changing out of the alloy. Some need to be reballed in applications where high reliability interconnections need to be formed. The most common conversion of the alloy is from a SAC lead-free alloy to an Sn63Pb37 alloy ball for various defense, aerospace or space applications where the use of lead-free solders are not allowed due to tin whisker concerns. BEST’s primary experience is in the reballing of BOTH lead free and leaded solder alloys with occasional specialty solder ball types (solder coated copper spheres) and solder alloy balls (10/90, Sn-Bi, etc) being accommodated.

There are a variety of guidelines and specifications which drive the various methods and processes for reballing BGAs. BEST is aware of and can follow these specifications whether they be based on general electronic assembly industry or space guidelines or high reliability defense specifications. The IPC 7711 and 7721 Rework, Modification and Repair of Electronic Assemblies guidelines define for the general electronics industry use several methods for reballing BGAs. The GEIA-STD-0006 Requirements for the Using Solder Dip to Replace the Finish on Electronic Piece Parts standard is one used by many defense industry OEMs and contractors to dictate the reballing process which may be used. In addition, the IEC TS 62647-4 Process Management for Avionics - Aerospace and Defense Electronic Systems is typically employed for reballing devices for use in the space and defense electronics applications.

Reballing Plastic The tools, materials, know-how, equipment and process expertise is something that is gained over time and experience by an outsourced reballing servies provider. The experience BEST has gained in reballing tens of thousands of devices on hundreds of different pattern configurations, body styles and package materials has shaped the understanding of reballing for a variety of industries. The tools we use for reballing are controlled, designed and manufactured in house. These tools include metal and plastic film stencils, reballing preforms along with holding and tooling fixtures. Because we build them under one roof, lead times are controlled, quality is assured and changes as the process is developed further can be accomplished quickly. The equipment required for reballing including solder fountains for deballing, hot air non-contact extraction for deballing , automated ball placement equipment, automated 3D inspection equipment and more are located within our company. The reballing expertise gained over hundreds of thousands of reballed components and vertical integration of capabilities makes BEST a well-known source of reballing expertise.

Reballing Plastic The tools, materials, know-how, equipment and process expertise is something that is gained over time and experience by an outsourced reballing servies provider. The experience BEST has gained in reballing tens of thousands of devices on hundreds of different pattern configurations, body styles and package materials has shaped the understanding of reballing for a variety of industries. The tools we use for reballing are controlled, designed and manufactured in house. These tools include metal and plastic film stencils, reballing preforms along with holding and tooling fixtures. Because we build them under one roof, lead times are controlled, quality is assured and changes as the process is developed further can be accomplished quickly. The equipment required for reballing including solder fountains for deballing, hot air non-contact extraction for deballing , automated ball placement equipment, automated 3D inspection equipment and more are located within our company. The reballing expertise gained over hundreds of thousands of reballed components and vertical integration of capabilities makes BEST a well-known source of reballing expertise.

While several device manufacturers do not recommend the reballing of their devices due to the excessive number of thermal cycles potentially impacting die reliability, BEST has successfully attached solder balls to every major device type. (Our reliability study that we authored on the impacts of reliability can be found here.) By using a very experienced BGA reballing service provider, many potential reballing process pitfalls can be avoided. A high yielding process saves BEST customers from having to spend hundreds of thousands of dollars in component acquisition costs. In addition, reballing has made available devices which are difficult to obtain in times of allocation thereby allowing the end customer to meet mission critical delivery times. By being aware of the potential reballing process pitfalls and through a long experience in reballing BGAs (BESTs’ experience goes back to the mid 1990s). Ceramic or metal BGAs are reballed using a different more complex process which BEST has amstered.

Each of the reballing methods used by BEST Inc. is equal in its outcome -the precise reattachment of solder balls onto area array devices or interposers. We make sure that we properly handle the devices from both a ESD and MSD perspective as well as mechanically handling the delicate components when performing BGA reballing. The method chosen for BGA reballing is determined by several criteria including:

There are numerous methods which BEST can employ to perform the BGA reballing - from a large 50 x 50 mm package with thousands of IO and high temperature spheres attached to a ceramic substrate to a very tiny 1.5 x 1.5mm plastic package containing just a few solder balls to 6 mils in size. These methods can be utilized from a lot size of one piece up to a production quantity of tens of thousands of devices. The methods can be categorized most simply by the method of ball attachment knowing full well that there are numerous methods for device preparation/deballing. The simplest categorization using the different ball attachment methods are:

In addition to theses methods there are many different ancillary services that at times are requested as part of the reballing service including but not limited to salvaging, cleaning, marking, tape/reeling and other analytical testing services.

BEST Inc engineering staff can also consult with you on your BGA reballing processes. If you need to develop acceptance criteria for other service providers or for internal development, then BEST Inc can be your solutions provider. We can also diagnose and troubleshoot the difficulties you may be having with your own BGA reballing process. Whatever the BGA reballing process you need BEST Inc can provide a solution.

BEST, unlike other reballing service providers, can create preforms, stencils and tooling in-house to facilitate the reballing of a component. This allows us to provide reballed components in a more timely fashion while controlling the quality, including process reballing challenges.

The BEST BGA reballing process can be outlined in the following process steps, each one of which is documented on the internal job order traveler.

|

For receiving a quotation from BEST Inc please contact us at info@solder.net or call to speak with a representative at 847.797.9250.