Overview Benefits FAQs Instructions Articles Sales Lit

BGA StencilQuik(TM) stencils-a quality solder paste stencil solution.

BGA StencilQuik(TM) stencils-a quality solder paste stencil solution.  Vision Award - Product of the Year StencilQuik™, previously honored with the coveted Vison Award for Product of the Year under the Rework Products category, is now a standard procedure in IPC 7711 5.7.2

Vision Award - Product of the Year StencilQuik™, previously honored with the coveted Vison Award for Product of the Year under the Rework Products category, is now a standard procedure in IPC 7711 5.7.2

Are you frustrated by the time it takes to repair mask damage underneath the BGA during the rework process? Are you squeezed for space on the PCB in and around the BGA area being reworked? Do want to ensure that a reliable rework process is used that subjects the BGA to a minimal number of heat excisions? We have an answer to your frustrations------ StencilQuik™. This breakthrough method allows you to simplify area array device placement/replacement saving 50% or more of the time required to rework BGAs or CSPs.CSPs.

Whether you are using paste flux or solder paste StencilQuik™ BGA rework stencil greatly simplifies your rework process while providing for a more reliable connection This method features a unique stay-in-place feature which simplifies the placement while increasing the yield of reworked BGAs.

These flexible solder paste BGA rework stencils remain in place on the site location becoming an integral part of the PCB assembly. StencilQuik™ is manufactured from a polyimide film with a high temperature adhesive covered with a release liner. It is the same type of material you have been using with bar code labels and for protecting gold fingers during the wave soldering process. These BGA stencils are laser cut from high quality, anti-static polyimide film with a residue-free high temperature adhesive backing. The StencilQuik™ apertures correspond to the land patterns on the PCB and define those portions of the PCB which are to have paste or paste flux applied.

The StencilQuik(TM) stay in place BGA rework stencil is something you can rely on. It is part of the IPC 7711 BGA rework processes. There have been numerous reliability studies which have been proven the StencilQuik(TM) rework stencil dependable. See copies of the studies here and here. In addition a 3rd party has independently verified that the SIR characteristics of a BGA with a StencilQuik(TM) placed using the stencil with paste and paste flux have more than acceptable SIR (surface insulation resistance) values when placed onto a PCB.

|

|

|

StencilQuik™s are packaged in groups of (10) in a small antistatic poly bag. They are NOW available in 4,6 and 8 mil thicknesses with an electronics grade adhesive. Squeegees are sold separately.

StencilQuik™ A faster more reliable rework process

1. Prepare site.

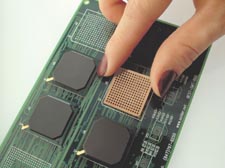

1. Prepare site.  2. Align and affix the StencilQuik onto the PCB.

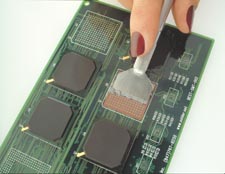

2. Align and affix the StencilQuik onto the PCB.  3. Squeegee paste or apply flux into the apertures on the RCB.

3. Squeegee paste or apply flux into the apertures on the RCB.  4. Simply align and place part and reflow.

4. Simply align and place part and reflow.