Laser Services

Rework / Repair Services

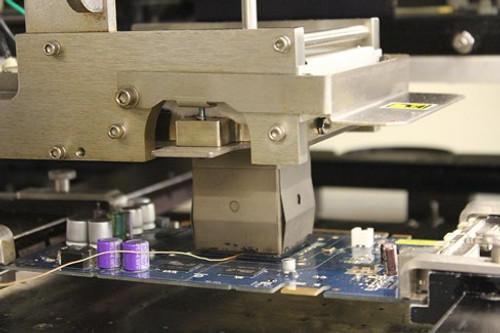

Laser micro-machining on PCBs requires that materials are either cut through, partially cut through, scored or marked in a very precise and repeatable fashion. BEST has the capability to precisely machine your PCB assemblies and components for marking, rework or production requirements.

Laser micro-machining on PCBs requires that materials are either cut through, partially cut through, scored or marked in a very precise and repeatable fashion. BEST has the capability to precisely machine your PCB assemblies and components for marking, rework or production requirements.

BEST's laser tools are micro-machining systems with a broad range of capabilities. BEST has a variety of laser micro-machining sources including CO2, YAG and green laser source with a variety of beam delivery and machining tables. Feature sizes down to 10 microns are possible with these systems. Materials which can be processed by BEST for laser micro-machining include but are not limited to plastics, glass, wood, thin films, metals, ceramic and other organic materials. We can take in a variety of file types including GERBERS, AUTOCAD, jpegs, tiff and giff and other file types.

|

Laser Wire StrippingBEST Inc is the best source for Laser Wire Stripping projects. This stripping technology was developed in order to reduce the risk of damage to both conductors and insulators using other wire stripping methods-especially mechanical methods. There are numerous benefits of laser stripping compared to other stripping approaches that have helped this technology gain favor. |

Kapton Laser MachiningLet BEST In. be your source for laser machining of Kapton™ . We can cut out patterns, drill holes, assemble parts and mark on Kapton™ materials |

De-panelingLasers can be used to depanel individual PCBs from panels. In addition laser depaneling is often used when very tight tolerances are required for PCBs such as when there is very little room in an enclosure that the board is fitting in to. For the ioT applications very small boards in a variety of non-traditional shapes may need to be precisely cut to fit into enclosures. |

Medical Device Laser MachiningBEST Inc. can be your partner in medical device laser machining. We can cut holes, do precision laser machining or precision marking of a variety of materials including plastics, metals and more. |

|

CleaningLasers can clean conductive pads of many types of materials. This method is far cleaner and neater than mechanical or chemical methods. |

Flex Circuit Material RemovalFlexible circuits can be laser drilled or laser skived to produce through vias, blind vias or to remove dielectric material and expose conductive pads or fingers. |

Coverlay Coverlay Coverlay can be laser machined by BEST Coverlay Coverlay can be laser machined by BEST |

|