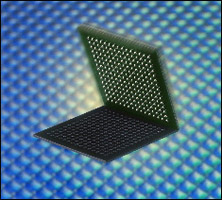

EZREball™The solder EZReball™ preform technique (IPC 7711/21 5.7.5.) used for reballing area array devices is one of the methods used at BEST for the attachment of solder balls. This BGA reballing process was developed primarily with the speed of attachment and simplicity in mind. The key to this method is the engineered polyimide and other polymer-based carrier ("preform") which holds the solder balls in place. After applying flux to the bottom of the part, the balls and part land patterns are aligned and “squared up” with the device. This aligns the land patterns of the device to the preforms' ball locations. The assembly is then reflowed. After being cooled the reballing preform is simply peeled away. Finally, the part is cleaned and inspected.

EZREball™The solder EZReball™ preform technique (IPC 7711/21 5.7.5.) used for reballing area array devices is one of the methods used at BEST for the attachment of solder balls. This BGA reballing process was developed primarily with the speed of attachment and simplicity in mind. The key to this method is the engineered polyimide and other polymer-based carrier ("preform") which holds the solder balls in place. After applying flux to the bottom of the part, the balls and part land patterns are aligned and “squared up” with the device. This aligns the land patterns of the device to the preforms' ball locations. The assembly is then reflowed. After being cooled the reballing preform is simply peeled away. Finally, the part is cleaned and inspected.

The major advantage of this technique is in its convenience as the solder balls are packaged inside of the preform. Each unique solder alloy, ball size and grid pattern requires a new preform. which can be engineered and fabricated in a few days at BEST Inc.

Materials Required

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

After confirming the drawing with the user, the preforms are designed, laser machined and populated with the proper-sized balls along with the proper alloy. Assuming the lands of the component are already prepped, water soluble paste flux is spread onto the pads of the component. The BGA preforms are then aligned to the package making sure of the proper orientation of the preform to the package. The package being reballed sits with the ball side up in order to get the best possible ball attachment. A properly-profiled reflow source then attaches the solder ball to the package.

After being cooled the EZReball™ preform can be pulled off of the package. Using the right cleaning solution and a clean soft brush the flux and adhesive residue can be cleaned off the package. The package can be air dried using either a static neutralizing gun or with nitrogen.