PCB Inspection Services PCB Inspection Services

BEST offers a variety of analytical testing services to help you spot and trend defects, process or part changes. Visual, Endoscopic, and X-RAY inspection , as well as dye and pry inspection services are offered by BEST in order to help you diagnose and troubleshoot and sort out a variety of defects. Our highly trained staff is able to assist you in analyzing specific defects.

|

AOI INSPECTION AOI INSPECTION AOI INSPECTION AOI INSPECTION

BEST offers automated optical inspection services for those requiring the inspection of assembled or partially assembled printed circuit boards. AOI systems use high speeds cameras and calibrated light sources to capture real time images comparing them to the criteria and tolerances built in and programmed boundary conditions which are acceptable. These acceptance criteria are generated by using the current industry IPC-A-610 Acceptability of Printed Circuit Board criteria plus BEST industry and inspection experience to determine the accept/reject criteria.

We offer this AOI inspection service to those who want to have a third party, qualified resource to inspect the work of a contracted electronics assembler. Overflow work or work for OEMs and CMs not having this capability is also done by BEST Inc. This inspection along with X-ray imaging and visual inspection will provide you with the full board inspection coverage for determining the outgoing quality level of the build. AOI Inspection Services

|

Visual "Referee" Inspection Visual "Referee" Inspection Visual "Referee" Inspection Visual "Referee" Inspection

BEST can be your "referee" resource when clarification is required regarding a PCB or wire harness acceptance standard interpretation. Our Master Instructors, who are military trained and have been Master Instructors for the IPC A 610 courses for many years can provide a "third set of eyes" when an issue arises in the PCB assembly process. We can provide a detailed report for refereeing purposes. When you need an outside expert opinion, or when you need to determine the existence of a PCB assembly process problem.

Wire harnesses and cables can also be inspected by BEST Inc. personnel on a contract basis per the latest IPC-A-620 wire harness and cable inspection criteria.

|

Endoscopic Inspection Endoscopic Inspection Endoscopic Inspection Endoscopic Inspection

BEST uses a dedicated BGA/CSP endoscopic inspection tool in order to see underneath SMT parts. Defects like opens and voids are some times difficult to discern-even with XRAY equipment. That is why BEST has the latest in inspection tools available for its customers including a high-powered endoscope system that allows BEST technicians to actually see underneath BGAs, CSPs and even flip chips.

Several characteristics of the solder ball can be determined with this tool. The actual standoff height, as well as degree of warpage, can be measured. Capture software allows for both absolute and relative measurements. This allows BEST to help you set up QC measurements for real-time references for the boards being inspected. Several defects can be measured and recorded via .jpeg or .mpeg images. For example, solder joint cracks in connections inside, outside or under the component body can be seen. Micro-cracking of the component body (popcorn effect) without component removal can also be seen using this tool. In addition, flux residue trapped under the component after soldering can be documented.

|

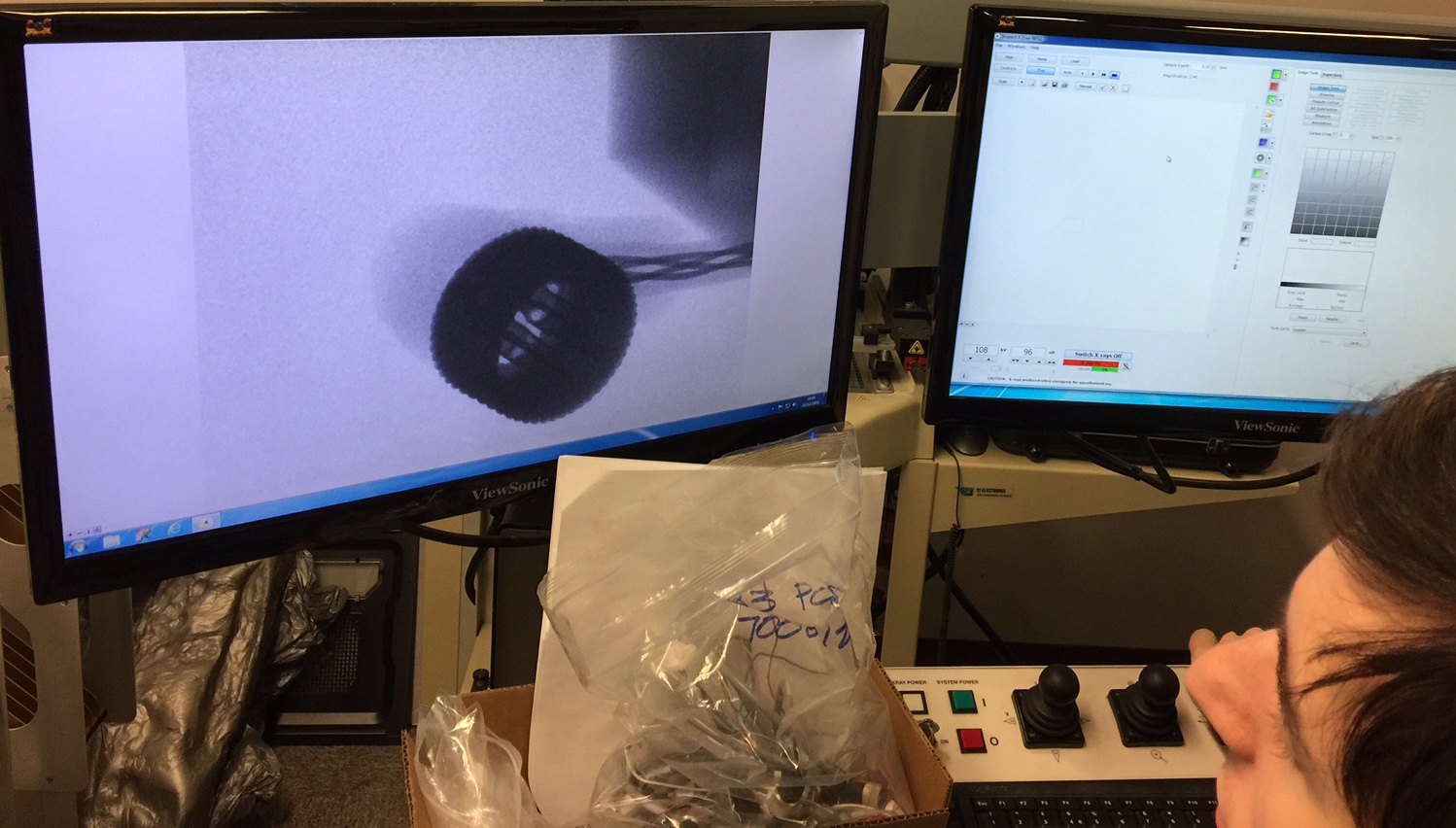

X-RAY Inspection X-RAY Inspection X-RAY Inspection X-RAY Inspection

X-ray inspection has become a generally accepted method to control the quality of board assemblies and to analyze defects of hidden solder joints. It is key to efficient implementation and monitoring of the reflow process for BGA, CSP and flip-chips. For optimal use of this tool both the right equipment along with a properly-trained staff, which can properly interpret the results and their relationship to process and component variables, should be used.

Skilled XRAY technicians like those at BEST make a difference in being able to help you detect process problems or screen for known defects. For instance, some defects such as bridges can be "seen" directly while others can only be detected by their signatures. The correspondence of the signatures to the various defects is known from experience, but can be understood from simple geometrical considerations. For example, if a single BGA solder joint appears brighter than its neighbors, it is obviously not as thick and, hence, must be open (not properly soldered). BEST skilled X-ray technicians can help you screen for defective products based upon yours or BEST's developed acceptance criteria for the given defect. X-ray Inspection Services

|

Dye and Pry BGA Inspection Dye and Pry Dye and Pry BGA Inspection Dye and Pry

"Dye and pry" technique, which relies on a liquid dye that penetrates into existing micro cracks or under open solder balls is a destructive test method for the revealing of defects on the solder ball to pad interface (see figure below). After letting the dye dry, the BGA is "pryed" off its PCB and the solder balls are inspected for the presence of the dye which reveals the location of the inter-facial connection problem area. Dye & Pry Services

|

High Resolution Video Inspection High Resolution Video Inspection High Resolution Video Inspection High Resolution Video Inspection

BEST’s high resolution video inspection services are backed up by high precision metrology equipment. We have both manual and automated tools, all of which have been routinely factory calibrated These tools allow us to resolve measurement to less than a micron.

If you need precision measurements of your components, PCBs or other high precision parts then BEST’s high resolution video measuring services may be your solution.

|

WIRE HARNESS AND CABLE INSPECTION WIRE HARNESS AND CABLE INSPECTION WIRE HARNESS AND CABLE INSPECTION WIRE HARNESS AND CABLE INSPECTION

BEST’S trained master instructors in WHMA/IPC-A-620 can inspect your or your customer’s wire harness and cable assemblies. We can review the assemblies you are receiving from your sub contractor as a third party inspection resource or provide “referee” services is there are disagreements between you and your assembler. If you require these service find out more about them here

|