BEST Inc. has IPC certified cable and wire harness specialists who can inspect the cable and wire harnesses per IPC-A-620 standards. Our trained inspection staff as well as instructors are available to make calls based on the documentation and inspection criteria supplied by you. Let us be your outsourced “referee” cable and wire harness inspection arm. If you would like to verify your processes we can work with you on taking measurements for your R/R studies and analysis.

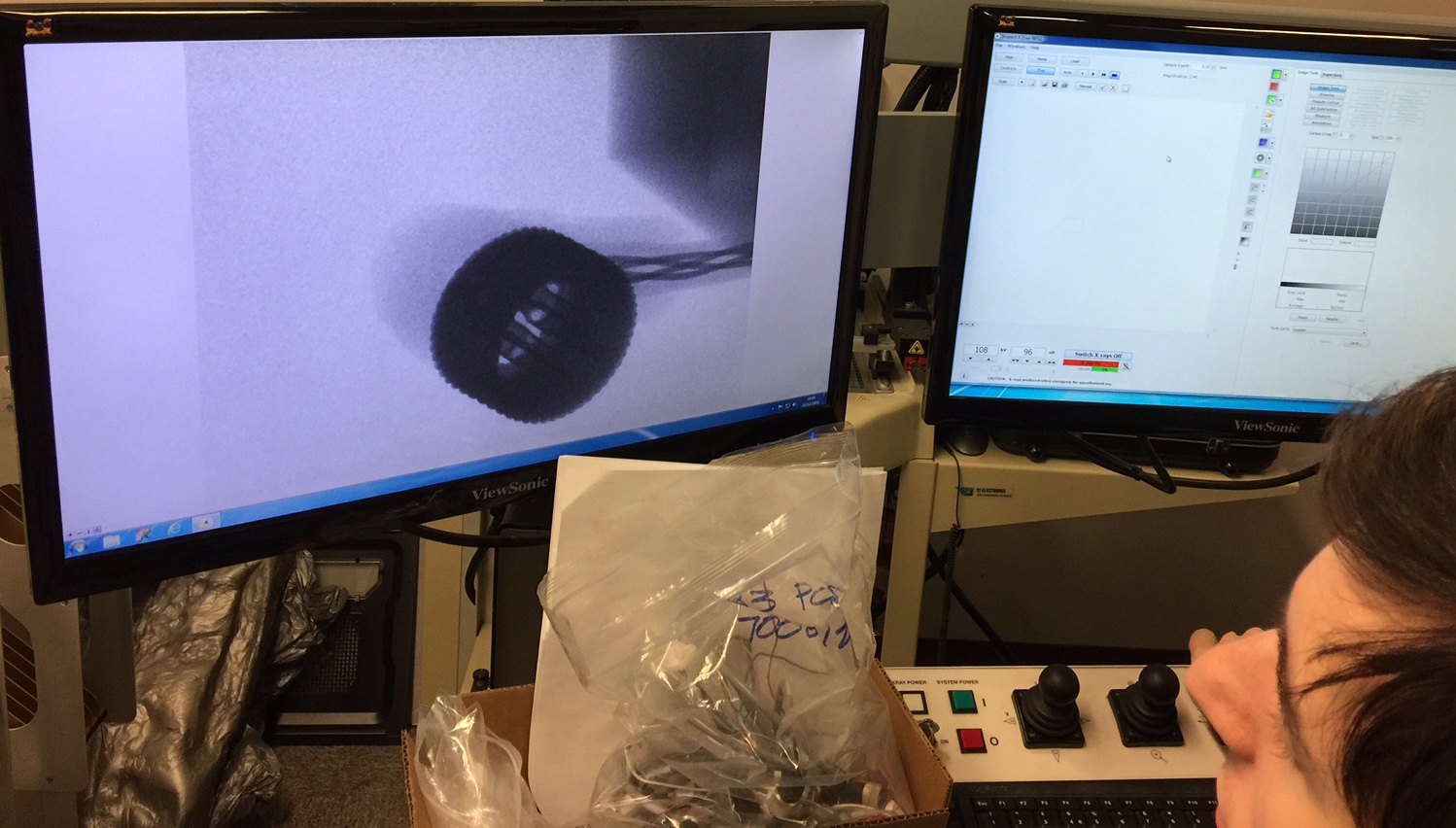

BEST can provide a variety of documentation services on the inspection of wire harnesses and cables. Not only can we document findings including both acceptable, process indicator and defect conditions of the cable or wire harness workmanship but we can also provide digital photography as objective evidence of our “calls” on the inspection. BEST can also make measurements of cable lengths and other called-for dimensions from the print. BEST can provide x-ray inspection services for those connectors which are overmolded. We can even cross section parts of connectors or cables to help make calls on problem issues with the assemblies.

BEST can provide a variety of cable and wire harness testing services including both the above-described visual inspection as well as mechanical and electrical. Mechanical testing of cable assemblies can be done via destructive pull testing whereby a wire is pulled at a fixed rate of speed to failure or for a set period of time. BEST has automated and calibrated pull testing equipment which can be used to perform destructive mechanical pull testing. In addition to pull testing BEST has calibrated instruments in order to measure the crimp height. In addition other types of mechanical testing can be performed by BEST based on your other requirements. Electrical testing can be accomplished by BEST personnel in order to determine the electrical characteristics of the wire crimps to the cable conductor or other connector pins based on the drawing. BEST technicians and QC personnel can read and interpret these prints to perform this testing. In some cases overvoltage stress testing can also be performed as part of the electrical cable and wire harness testing.

|

Inspection of buried, imbedded or overmolded connections can be done with saved images of anomalies |

|

Crimp height can be analyzed and measured. |

|

Testing can be performed and analyzed by IPC/WHMA-A-620 master instructors. |