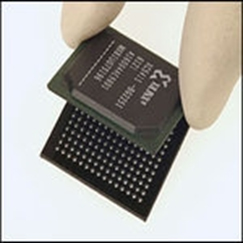

In this technique, described in IPC 7711/21 in the 5.7.5 procedure, soldering preforms are used in order to replace solder balls. Solder preforms are single use pre-loaded preforms which are embedded in the pattern corresponding to the device to be reballed. The BEST EZReball™ preforms are custom-made and correspond to the customer-supplied drawing or the mechanical data sheet of the component. This greatly speeds the reballing process while simplifying reballing. The technique is well-suited for small to medium lot sizes.

The process below is generic in nature and is adopted to the customer specifications, lot size and the type of component being reballed. Reballing process considerations and other analytical testing considerations can be found here. Proper mechanical handling of devices including ESD, MSD and handling of BGAs can be found here.

|

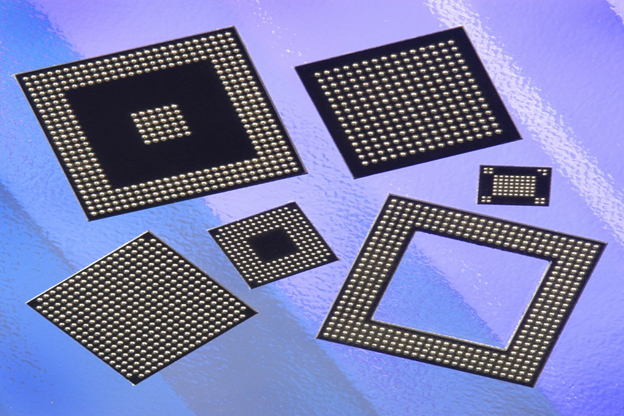

The solder reballing preform technique is used when a small or moderate number of the same part pattern devices need to be reballed. When the component or interposer has a large number of balls this is the preferred technique as the preforms can be preloaded and the reballing process time is reduced.