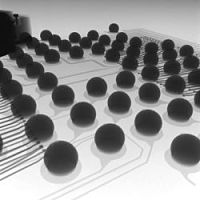

BEST's BGA x-ray capabilities, like the rest of its BGA service offerings, is extensive. BEST can be your outsourced BGA x-ray inspection partner for BGA, leadless device, system in package and stacked packages. If you are assembling these packages onto boards but do not have internal x-ray capabilities; then consider outsourcing this to BEST until the time comes when you can spend the capital on bringing this capability in-house. After programming your board into our x-ray system we can automate the follow-on steps for subsequent BGA inspection making the time and cost lower over time.

For the in-depth analysis of BGAs, BEST's X-Ray Inspection system can give you the following BGA x-ray inspection capabilities:

So whether you are looking to have your BGAs from manufacturing x-ray analyzed or dig deep into a root cause of BGA manufacturing issues you are experiencing, BEST can be your outsourced BGA x-ray inspection provider.

We can get you crisp images of every single location along with the reference designator or even a movie as we "drive around" the BGA to show you the anomalies noted by the x-ray technician. CSPs, BGAs, and POPs can be x-ray inspected by the BEST technicians. Large thermal mass boards (160KV plate voltage) with tiny feature sets (3um spot size) are not a problem for our x-ray system. Micro BGA x-ray inspection, as well as column grid array packages, can be x-ray inspected using our x-ray system. A full report, partial report, images fully or partially annotated x-ray analysis can be done by our BGA technicians as they are highly skilled at shooting images as this inspection is part of our standard BGA rework process. These are just some of the BGA inspection services which can be provided by BEST Inc.

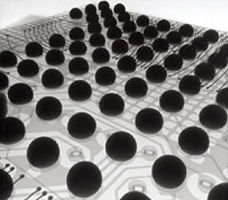

BEST can also provide detailed BGA x-ray inspection services whether it be for process troubleshooting, failure analysis or determining the cause of other BGA location failures. BEST can provide in-depth BGA x-ray analysis including but not limited to the following:

Ball circularity measurement will determine the consistency of the collapse, the presence of head-in-pillow defects, shorts or contamination on the pad

Ball diameter-ball measurement will determine if there are shorts, a lack of collapse or missing solder volume. Void percentage-will tell the BGA x-ray inspection technician if the reflow temperature has been held, the flux is expired, there is pad contamination, outgassing from the ball or pad, as well as numerous other anomalies

Call BEST today to see how we might be able to be of service for your BGA x-ray inspection or BGA x-ray screening requirements.