BEST offers BGA x-ray inspection services in order to confirm rework, help diagnose process problems and make sure the inspection criteria of your customers are adhered to.

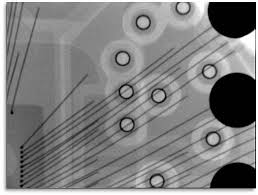

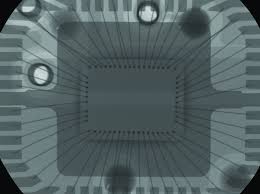

BGAs by their design and attachment to the PCB require an x-ray system to confirm solder joints underneath the package of the device and to insure that the assembly or rework process is in control. The wetting characteristics, the uniform collapse of the solder balls, the minimization of voiding as well as the integrity of the wire bonds can be assured with the use of x-ray imaging. By manipulating our x-ray system, the interface of the ball both to the PCB and the package can be confirmed.

X-ray imaging is also used to detect a variety of soldering and device anomalies that can occur in the assembly process. These anomalies may include:

For higher volume BGA rework or inspection automated routines can be set up. BGA x-ray inspection can confirm the consistency and repeat-ability of the process. A report which can generate the concentricity of the solder balls, ball diameter, solder void percentage and other attributes can all be outputted to a report. Any defects outside of these set parameters can be flagged and the specific location closely examined.

Call BEST today to see how we can help you qualify your BGA assembly process or perform contract x-ray inspection services without investing in the capital outlay of your own x-ray machine.