As the complexity of electronic assemblies has increased and the corresponding miniaturization of components populating those assemblies have shrunk, the ability to confirm the proper assembly of these boards has gotten more complicated. Long gone are the days when simple visual inspection of the finished assembly by a set of trained and experienced eyes was sufficient to confirm that the board was properly assembled. Fast forward to today where tools such as the automated optical inspection of electronics makes for a reliable consistent inspection. These tools are programmed such that the pickup of the sensor images is reviewed rapidly and compared with the programmed values. The values which are flagged are then reviewed by a trained and certified inspector which makes a “call” on the validity of the anomalies. Those “calls” which are confirmed defects are logged into such software and are marked for subsequent rework via a rework label. Those which are “false calls” and deemed to be acceptable are marked as such in software. In this way many boards of high complexity can be scanned and reviewed.

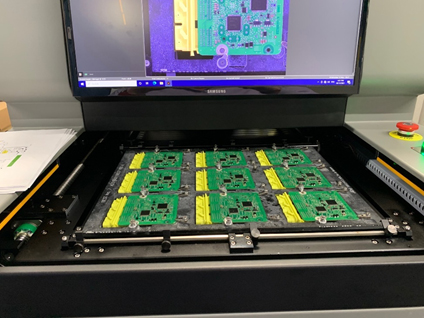

The programming of the AOI inspection machine takes skill and right kind of inputs. The programmer takes in the XY data, the bill of material and GERBER files in order to generate the AOI program file. The programmer takes into account the location of the components, the type of components and the IPC class of the assembly when programming. Experienced programmers can take into account unique components and configurations based on their experience and their knowledge of IPC-A-610 Acceptability of Printed Wiring Assemblies. BEST also has the right engineering expertise to get fixtures fabricated in order to speed up the throughput of the AOI inspection process.

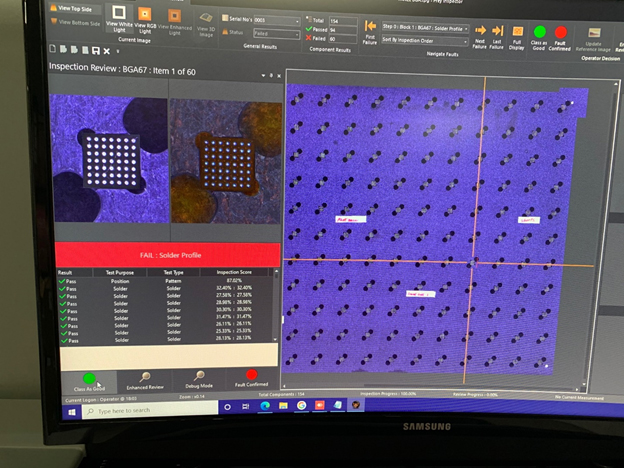

Running through board assemblies takes someone experienced and skilled in the art of PCB inspection. Experienced operators require knowledge of how the software of the AOI machine works, how the lighting impacts the area of interest and how the surrounding areas impact the image quality. In addition to this understanding, AOI operators are experienced and certified in the IPC-A-610 inspection guidelines. Both their experience and knowledge of the standards allows for them to make the appropriate “calls” flagged by the AOI inspection system.

In addition to the trained programming and machine operators running the AOI system it is important to have a system which is reliable, one that can “see” today’s components and the solder outline which mechanically attaches them to the PCB. The AOI system should also have reporting capabilities for SPC data collection as well as fast processing capability in order to get through complex builds in a reasonable measure of time.

There are several anomalies which a modern AOI system should be capable of finding including but not limited to the following:

BEST can be your outsourced AOI PCB inspection provider. We can inspect the boards produced by a vendor of your choosing and be the “referee” when it comes to meeting your inspection criteria. Boards can be covered by AOI inspection and may need to be combined with X-ray and visual inspection in order to get a complete scorecard on the assembly quality of the PCB. BEST can mark the defect areas of the PCB or we can provide the turnkey solution for not only noting the defects or anomalies but also reworking these defects based on a time/material estimate. BEST can also “offload” your AOI inspection work if you are a contract manufacturer and your AOI system is down for maintenance or your workload is at capacity in your inspection area. BEST can also offer this service to smaller contract manufacturers or OEMs not having onsite AOI inspection capability.

AOI is the accepted method for inspection of printed circuit boards which have been assembled. This inspection methodology offers faster inspection speeds identifying errors in real time. It can provide a repeatable and reliable method for catching soldering as well as other assembly anomalies.

If you are looking for tested and good-quality PCBs or assemblies, it is crucial that you source them from a reputable PCB assembler using best in a class practices following IPC J-STD-001 processes. In addition, inspection should be accomplished using IPC-A-610 certified inspectors. Tools such as AOI inspection coupled with x-ray inspection of non-inspectable areas of the PCB such as BGAs, LGAs, QFNs and some connectors will help ensure that the assembly is from an assembly point of view and as close to error-free as possible.

|

AOI Inspection Technology: |

Algorithm-based, image modeling |

|

Inputs required: |

Bill of material, XY data, Gerber (Fastest method) |

|

Board Sizing: |

26 x 22” (mm) |

|

Resolution: |

10um in X; 15 um in Y direction |

|

Minimum Component Size: |

01005 |

|

Inputs required: |

Gerber (Fastest method) |

|

Height accuracy: |

0.00003” (1um) |

|

Z resolution: |

0.0004” (10.1um) |

|

X/Y resolution: |

0.0003” (7.6um) |

Call BEST Inc. today to see how we can be a partner in your outsourced AOI inspection requirements.