High Volume Rework

HIGH VOLUME PCB REWORK

There are cases where large volumes of assemblies containing electronics, usually made in overseas factories, have landed in US, Canadian or Mexican factories and have design or manufacturing problems requiring rework. In some cases, problems have sprung up in field usage of the product or the product was “fast tracked” to get it to market and the testing was inadequate. This lack of testing did not bring to light the design defects until it was too late. In other cases, a manufacturing defect is discovered but the distribution and logistics pipeline is filled with lots of product and a large amount of product needs to be reworked. In some cases, a faulty part leads to product sorting and there is a need to rework thousands of finished assemblies.

BEST Inc. is a provider of la PCB and electronics rework when very large quantities of electronic assemblies need to be reworked. BEST’s engineering staff is creative when it comes quickly engineering high volume processes for reworking electronic assemblies. Our experienced staff has many years and project’s worth of PCB rework services from cell phones to supercomputers to 3D printers and coffee makers. BEST also has experience in wire and cable harness rework. We can also provide the mechanical rework services including taking the electronics assembly out of the housing and putting the reworked and tested sub-assembly back into the housing. These services can be further extended to logistical support including tracking of shipments, matching units to the proper overpack and reporting requirements back to you.

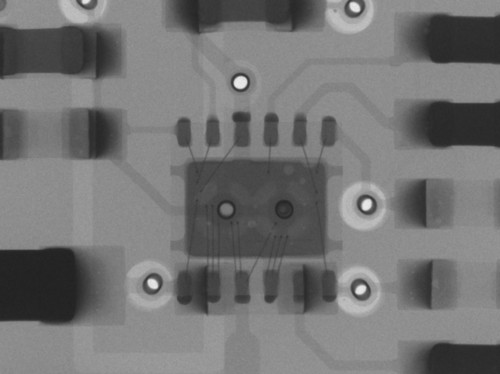

BEST has the right equipment set to go along with our expertise in engineering high volume PCB rework. Our shop has multiple high end rework systems along with the automated x-ray inspection equipment to go along with this kind of PCB rework. Our semi-automated soldering excavation system can provide non-contact solder removal. In addition, we have highly customized pick and place rework equipment that can place lots of missing or wrong components after having solder paste dispensed on pad locations or parts dipped in to fluxers. We even run the reworked boards through automated optical inspection on order to automate the inspection process.

BEST will process your high-volume rework project taking in to account the most up-to-date IPC standards. We have several master instructors who help keep the rework staff up-to-date on industry standards while keeping and training the staff in these standards.

You will not come across such an experienced rework engineering team with such an advanced equipment set to work on your electronics rework projects. Call BEST Inc. to see how we can be of service.