FAQs on X-Ray NDT Sorting

Below are some of the more common questions we are asked by BEST clients desiring x-ray NDT testing:

Q: What kind of image resolution can I expect of the x-ray images?

A: The image resolution varies based on the x-ray system being used. Scan resolutions range from 1 to 5 microns (0.04 to 0.20 mils).

Q: How are the parts fixtured during the X-Ray process?

A: Most fixturing is performed with low density material. For multiple parts requiring a highly repeatable setup, robust tooling fixtures or 3d printed fixtures are developed on a case by case basis.

Q: Can multiple parts be inspected at the same time?

A: Yes. Depending on the customer’s objective and the resolution required to effectively image out the results multiple parts can be inspected at the same time. BEST x-ray systems have a built-in step and repeat function facilitating this feature which needs to be programmed by the x-ray technician. Once an image is captured at the location of interest stepper motor drives the imaging system to the next location where it lands. The x-ray technician then evaluates the image based on the criteria established and a call is made and image gets captured. The next location is then driven to and process repeats itself.

Q: How large are the X-ray image files?

A: X-ray image files range from 200k to 15MB in size.

Q: How big can the samples be?

A: The maximum sample size is 28 x 30” (711 x 762mm) with a maximum weight of 11lbs (5kg).

Q: What is the x-ray imaging cycle time?

A: The imaging itself only takes a few seconds but the loading, unloading, viewing and examining, recording and sample manipulation are generally the longest part of the inspection cycle.

Q: In what file format are the initial results captured?

A: JPEG for pictures or MPEG for video.

Q: Do you sell industrial X-Ray inspection systems such as the ones you are testing my parts on?

A: No. We are a power user and x-ray services NDT provider.

Q: What is the timing for x-ray projects?

A: Most projects are completed with preliminary results in 5 days or less. Formal reports take some time to put together. If we have the capacity we can quote as an option an expedited project delivery schedule. Typical timing for projects is 5-10 business days. For projects of high volumes or those having detailed requirements, our lead time increases. For projects requiring expedited or 24 hour turn around, we do offer this service for a premium charge.

FLOW SENSOR

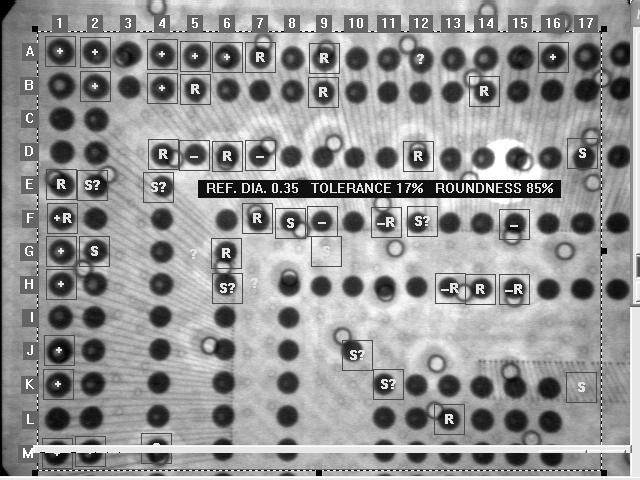

BGA Circularity Determination

Switch

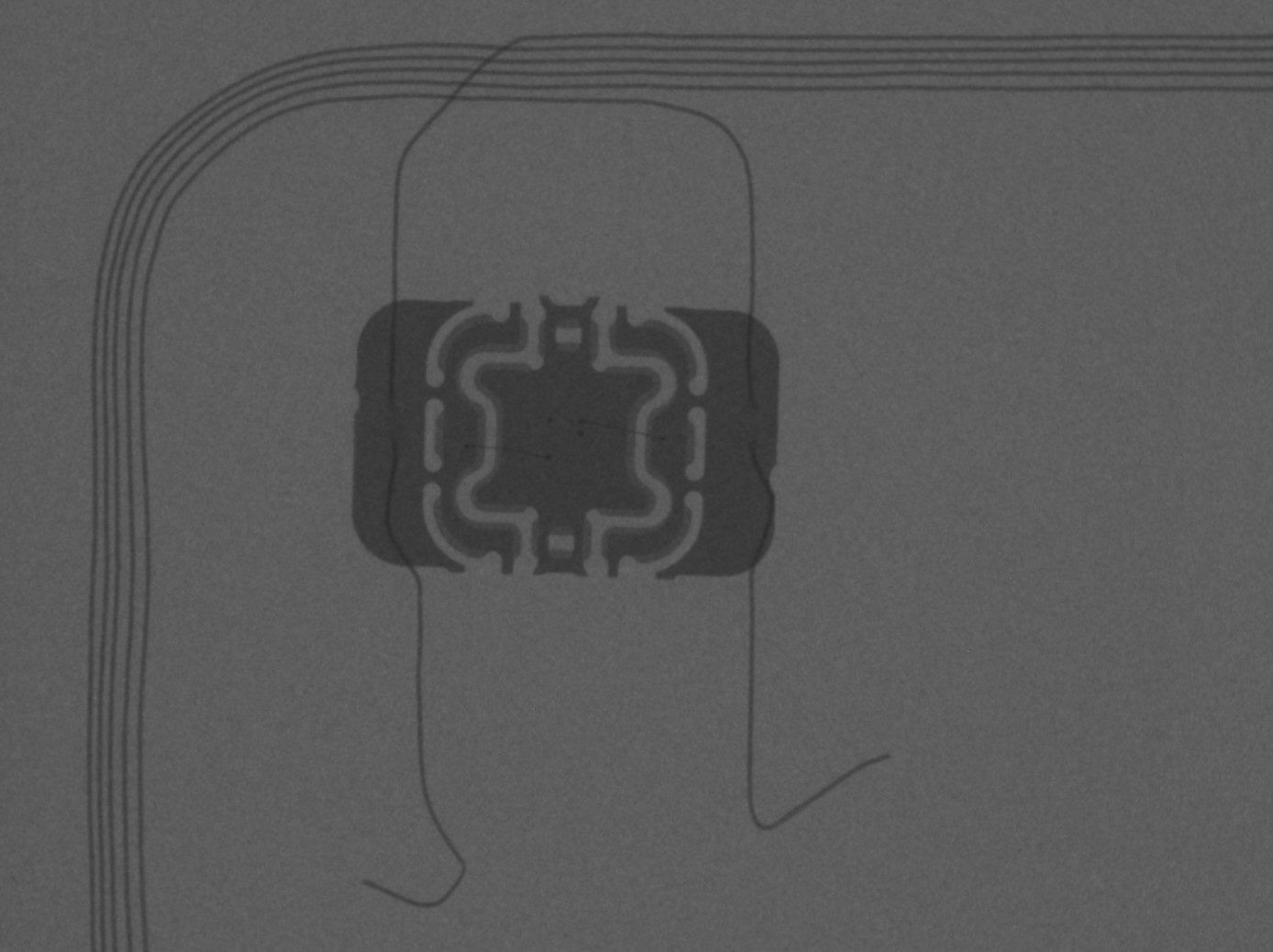

High Density Connector

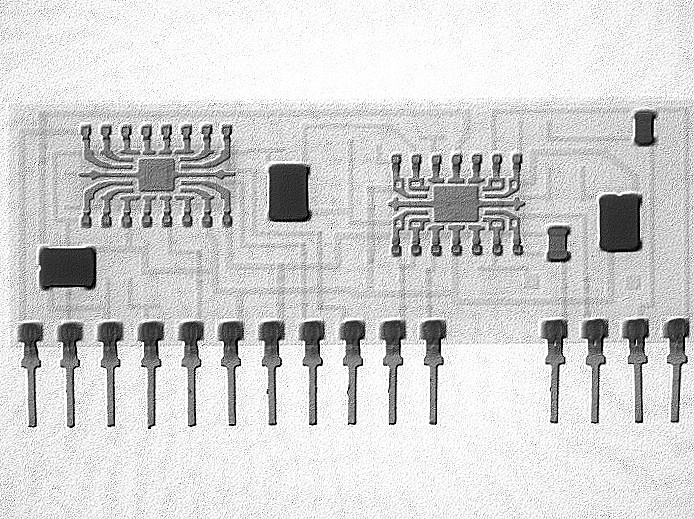

Hybrid encapsulated circuit

Handheld computer

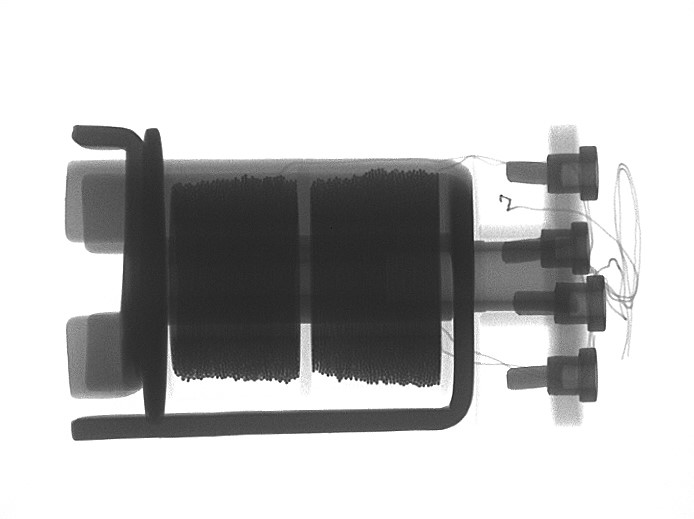

Large Coil

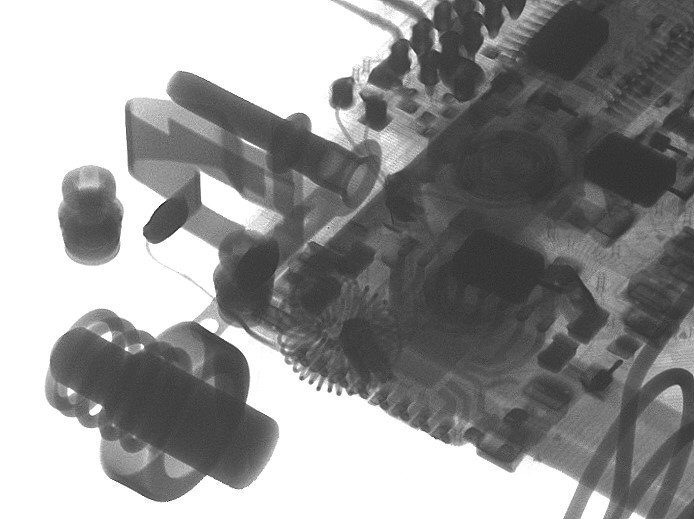

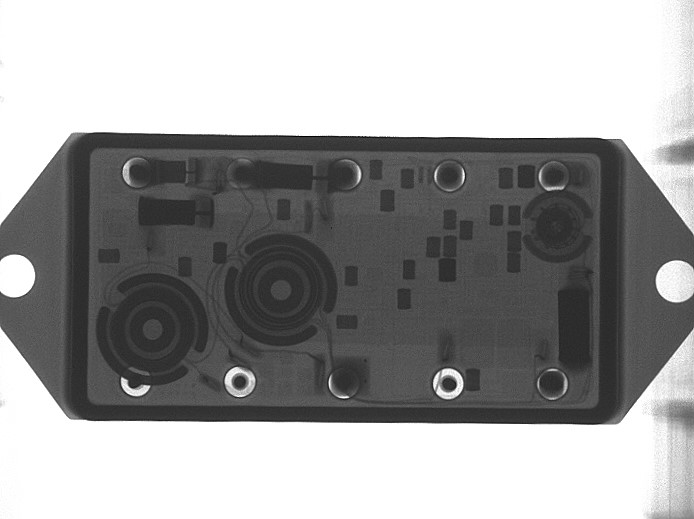

Control Module

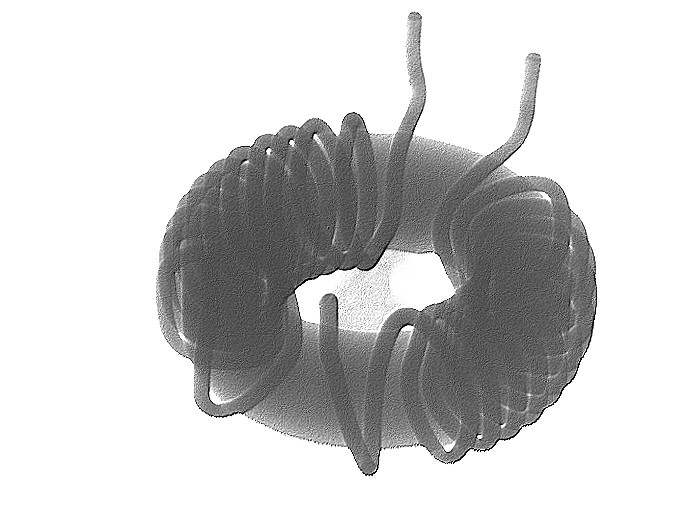

Coil

Smart smart-card