Fine Wire Stripping/Ablating

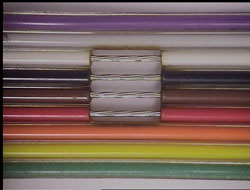

Window Paned Ribbon Cable Laser stripping is establishing itself as the best solution for the stripping of shielded, twisted and multi-filament cables. BEST can therefore meet the requirements of the aerospace industry in terms of laser wire stripping.

Window Paned Ribbon Cable Laser stripping is establishing itself as the best solution for the stripping of shielded, twisted and multi-filament cables. BEST can therefore meet the requirements of the aerospace industry in terms of laser wire stripping.

BEST Inc. can perform laser wire stripping on cables and wires in any desired location while not fraying the cables such as in a cut and pull off process. The BEST laser fine wire stripping ablation process allows for the removal of coatings from lengths of fine wire and cable while leaving a removable plug of coating on the very tips of the cable to prevent fraying.

36 gauge unstripped wire There are numerous applications requiring the use laser wire stripping is an assembly operation. These applications go across numerous industries including automotive, medical, aerospace and defense, data and telecom and consumer electronics. Ribbon cables, fine gauge wires, twisted wire and others require laser stripping, either end-stripped or mid-span. There is a vast array of applications for laser wire stripping within the medical electronics market. Specialist wire types to avoid interference are common place in control and display units-many of these require the precision of laser wire stripping. As another example ultra-fine gauge wires are used when probes must be inserted into the body in catheter devices. The defense sector have a wide range of wire constructions that are ideally suited to laser wire stripping. The common insulation types such as PTFE, ETFE, XLETE and Kapton are readily stripped by Carbon Dioxide source lasers. Telecom is an excellent market for the application of laser wire stripping. Multi-conductor, multi-layer shielded cables are common place allowing increasingly high data rates without interference. While the majority of automotive wires and cables are stripped using automated mechanical systems, inclusive of termination and even connector insertion, there are some applications requiring specialty wire types which lend themselves to laser wire stripping solutions.

36 gauge unstripped wire There are numerous applications requiring the use laser wire stripping is an assembly operation. These applications go across numerous industries including automotive, medical, aerospace and defense, data and telecom and consumer electronics. Ribbon cables, fine gauge wires, twisted wire and others require laser stripping, either end-stripped or mid-span. There is a vast array of applications for laser wire stripping within the medical electronics market. Specialist wire types to avoid interference are common place in control and display units-many of these require the precision of laser wire stripping. As another example ultra-fine gauge wires are used when probes must be inserted into the body in catheter devices. The defense sector have a wide range of wire constructions that are ideally suited to laser wire stripping. The common insulation types such as PTFE, ETFE, XLETE and Kapton are readily stripped by Carbon Dioxide source lasers. Telecom is an excellent market for the application of laser wire stripping. Multi-conductor, multi-layer shielded cables are common place allowing increasingly high data rates without interference. While the majority of automotive wires and cables are stripped using automated mechanical systems, inclusive of termination and even connector insertion, there are some applications requiring specialty wire types which lend themselves to laser wire stripping solutions.

36 gauge laser stripped wire Laser wire stripping is used in application requiring precision wire stripping, wire stripping of ultra-fine gauge wires or when a window pane of the strip is required. The precision of the cutting source from the laser allows strip lengths to be controlled to within a few thousands of an inch while assuring a very clean cut while not relying on a manual operation.

36 gauge laser stripped wire Laser wire stripping is used in application requiring precision wire stripping, wire stripping of ultra-fine gauge wires or when a window pane of the strip is required. The precision of the cutting source from the laser allows strip lengths to be controlled to within a few thousands of an inch while assuring a very clean cut while not relying on a manual operation.

Absorption of laser energy on the insulating layer means that the laser delivers enough energy to effectively remove the insulation by an ablation process. The photo-thermal means is essentially the heating and resulting evaporation of the insulator while the photo-chemical ablation process involves the breaking of chemical bonds in the material. These two types of laser ablation mechanisms produce very different results.

Absorption of the laser energy on the conductor/wire implies the delivered laser energy to the wire results in local heating that leads to evaporation of the surrounding insulating layer.

The two most common techniques for laser wire stripping involves either rotating a wire around its axis to expose all surface to one laser beam or one can direct multiple laser beams around the wire from several directions simultaneously. If a “window” needs to be ablated in the wire and the insulation needs to be removed, then a single beam with no rotation is sufficient. A machine vision system with an accompanying illumination technique may be needed to selectively strip certain sections on a ribbon cable or twisted wire. Generally speaking, the more beams, which is another approach, involves the overlap of the beams and allow for a more uniform circumferential coverage of the insulation to be laser-stripped.

BEST also offers semi-automated mechanical wire stripping of very small diameter wires-down to 40 Gauge. BEST has the capability to perform the following for wire gauges from 22 to 40 gauge:

- Cut to length

- Cut to and length and strip one or both ends, either with the insulation still in place or removed

- Window pane strip as well as cutting to length and stripping the ends of the wire

BEST can provide a variety of labeling and packaging solutions for this wire stripping service. You can be rest assured that the quality will be impeccable as BEST will inspect the cable assembly per the latest WHMA/IPC-A-620 guidelines.