Laser Marking

BEST can laser mark materials that have traditionally been difficult or impossible to mark with conventional printing and embossing methods.

Epoxy Part Marking BEST’s ability to laser mark many types of plastics, metals, glass, ceramic and other materials is the service best provided for those customers who have longed for a solution. Clearly marked serialization numbers, barcodes, and graphics can be achieved on your components to leave a lasting impression both in your material - and with your customers. Our laser marking machines are capable of laser marking metal of any type and on virtually any surface. We can laser mark a single part up to production quantities. Below are some BEST laser marking attributes:

Epoxy Part Marking BEST’s ability to laser mark many types of plastics, metals, glass, ceramic and other materials is the service best provided for those customers who have longed for a solution. Clearly marked serialization numbers, barcodes, and graphics can be achieved on your components to leave a lasting impression both in your material - and with your customers. Our laser marking machines are capable of laser marking metal of any type and on virtually any surface. We can laser mark a single part up to production quantities. Below are some BEST laser marking attributes:

- Laser Marking field: 12" x 18"

- Multiple fonts available including : Helvetica, OCR-A, bar code- 39, Script, Block, Gothic True Type

- Laser Marking

- Logo capability

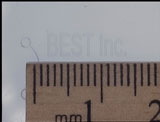

- Minimum engrave width 10 um

File Requirements

Marking of Glass CAD system integration and custom file converters enable flexible, laser manufacturing from user-provided data. Although most file types are accepted, the preferred file types are Gerber, DXF, or other 2D formats. In most cases, non-scaled data is required as BEST technicians will make the appropriate offsets and properly scale in order to meet part dimensions.

Marking of Glass CAD system integration and custom file converters enable flexible, laser manufacturing from user-provided data. Although most file types are accepted, the preferred file types are Gerber, DXF, or other 2D formats. In most cases, non-scaled data is required as BEST technicians will make the appropriate offsets and properly scale in order to meet part dimensions.

BEST is particularly proficient at the laser engraving of both numbers and letters. We are able to produce marks in metals with dimensions of just a few microns. Because laser marking is noncontact, small objects such as electronic components or circuits can be marked at hard-to-reach locations. Shallower or deeper marks can be obtained by changing the laser parameters.

Marking of PVC Cable BEST has a wide range of precision laser marking systems which can add clean, crisp marks onto your electronic products that are made of virtually any material. The materials which we have successfully laser marked include metals such as stainless steel, silver or platinum, as well as organic polymers, plastics, glass and ceramics.

Marking of PVC Cable BEST has a wide range of precision laser marking systems which can add clean, crisp marks onto your electronic products that are made of virtually any material. The materials which we have successfully laser marked include metals such as stainless steel, silver or platinum, as well as organic polymers, plastics, glass and ceramics.

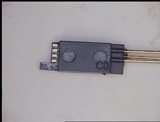

Marking of Component Laser marks are also indelible, add no contamination from solvents or inks and are difficult for counterfeiters to duplicate BEST has the capability to repeatably create spot sizes as small as 15 micron, allowing small products such as electronic components to be directly laser marked rather than depending upon paper labels.

Marking of Component Laser marks are also indelible, add no contamination from solvents or inks and are difficult for counterfeiters to duplicate BEST has the capability to repeatably create spot sizes as small as 15 micron, allowing small products such as electronic components to be directly laser marked rather than depending upon paper labels.

Marking of Stainless Steel BEST knows how to handle electronic and other sensitive assemblies. Our processes are tuned in to handle electronic assemblies as we know MSD and ESD processes and have properly-trained personnel. Our shipping department is familiar with how circuit boards should be handled. In short we take of your electronic assemblies as we care many different electronic assemblies each and every day. The laser marking of electronic components, assemblies and sub-assemblies is something BEST Inc. personnel are familiar with.

Marking of Stainless Steel BEST knows how to handle electronic and other sensitive assemblies. Our processes are tuned in to handle electronic assemblies as we know MSD and ESD processes and have properly-trained personnel. Our shipping department is familiar with how circuit boards should be handled. In short we take of your electronic assemblies as we care many different electronic assemblies each and every day. The laser marking of electronic components, assemblies and sub-assemblies is something BEST Inc. personnel are familiar with.

BEST understands the process for a laser marking job. We generally are receiving customer samples and manipulating the image and the laser setting to achieve your goals. Many times prototype tooling needs to then be created for a first article acceptance lot followed by manufacturing tooling in order to investigate the consistency of the process. This is followed on by subsequent manufacturing tooling in order to run production quantities.