PoP Rework

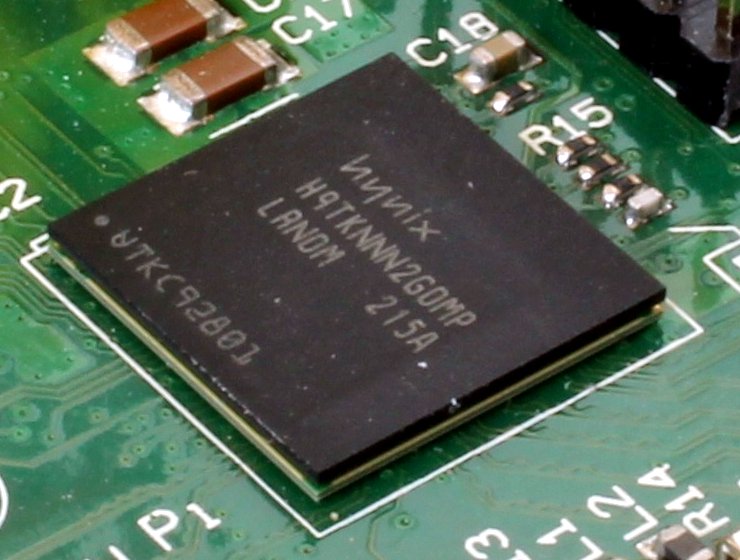

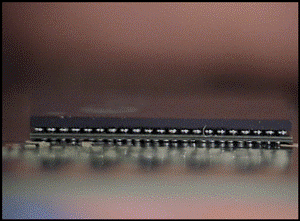

As board densities on consumer-oriented handheld devices continue to get greater board designers are relying on the Z dimension in order to get more functionality and design flexibility in less space. This is being accomplished by Package on Package or PoP package constructions whereby area array devices are placed on upon the next. This construction marries the CPU and memory together in some cases adding a third layer in terms of a co-processor to the mix. These packages tend to be high IO count, fine pitch very thin packages.

The challenges of reworking such a construction are several. Due to the thin size of the substrates these packages are prone to warping under the thermal stresses of the reflow cycle. In addition, they are difficult to inspect as their stacked nature makes it challenging to “see” via XRAY simple problems such as shorts. To add a further challenge many times these packages are underfilled meaning the removal of the device closest to the component being reworked or underneath the package being reworked has a high likelihood of being damaged upon removal.

BEST has used a variety of both traditional as well as novel rework techniques to solve these PoP rework challenges. We have been working with the following in order to getting the highest possible yields:

- Materials suppliers

- Device manufacturers

- Rework equipment suppliers

This has allowed our clients, the OEM community, to benefit by allowing BEST having process knowledge and experience with PoP rework. We have worked with a variety of commercial and military handheld device customers where PoP rework processing by the tens and evens hundreds of thousands has been performed by BEST Inc staff.

Our equipment is up to the task for PoP rework. We have BGA rework systems which allow us to remove solder on a non-contact scavenging basis, we have dispensing robots which allow us to dispense paste on odd-shaped land patterns typical of RF shields and other types of non-traditional reflow sources. Our XRAY and AOI systems are fully capable of being tools to diagnose and troubleshoot process problems while inspecting post rework. BEST can quickly build BGA reballing performs in house when devices need to be removed and replaced. We even in-house dye and pry and cross sectioning capabilities for further process development.

In addition to having the right equipment set, BEST has experience in using different materials as part of the PoP rework. Due to the fine pitches of these packages solder paste dipping is typically used for the individual package rework in order to ensure more consistent solder paste deposit volume which widens the process window. This also helps to ensure that flux residue left behind can be more easily cleaned. BEST also has experience with a variety of fluxes that help to insure that the PoP rework process is as consistent as possible.

Most importantly we have a dedicated, knowledgeable and IPC certified staff to help navigate through the various challenges of PoP rework. They have been working on PoP component rework for 10+ years and are constantly being challenged by our clients to come up with new processes for POP rework.

Call BEST Inc. today and see how we can be of service on your most challenging POP rework projects!