Overview Benefits FAQ Data sheets Instruction Articles

|

EZReball™ EZReball™ |

See how

EZReball ™ can speed up device reballing. |

|

EZReball ™ can speed up ceramic reballing. |

Are you tired of the existing reballing BGA methods being in the hands of process experts due to the complexities and the dexterity required? Are you looking for a faster reballing method? The BEST EZReball™ process is an answer to your reballing problems. In fact it is a recognized in IPC 7711/21 Procedure 5.7.6. as one of the ways to reball BGA. It allows for better yields and faster reballing times.

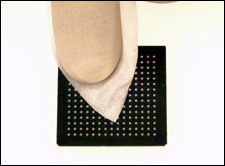

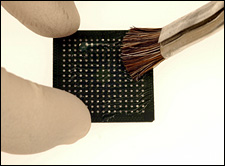

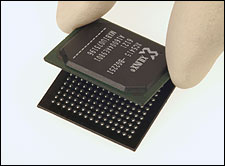

The simple nature of the EZReball™ BGA Reballing process allows even the beginning repair technician to reliably and quickly replace balls on a BGA package. Alignment is simple with the edges of the preform being “squared up” with the sides of the package thereby eliminating the need to buy custom fixtures or frames. The adhesive is engineered such that the balls are firmly held in place until after reflow thereby reducing the problem of missing solder balls found in other techniques. After the device has been reflowed, the preform is simply peeled off, eliminating the time required in cleaning off residual paper used in other methods.

The EZReball™ preforms are packaged and delivered to you the way you want. Preforms are custom made to your exact alloy and device array requirements without expensive tooling. They are also packaged such that developers and those building PCB prototypes can use them in quantities that are more reasonable.

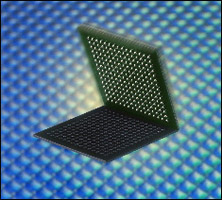

These BGA reballing preforms are a simple, elegant and easy-to-use reballing system. EZReball™ preforms are manufactured to your exacting specifications from a specialty high temperature-rated film which aligns the balls. The balls are aligned through these apertures and held in place using an engineered adhesive system. The preform is cut using a laser to your exacting device requirements. Solder balls are captured and retained by the preform and are aligned to the prepped device and re-flowed. After reflow, the preform is simply peeled away. EZReball™ Reballing preforms are packaged in groups of (15) in a small anti-static bag. Each packet also consists of (1) repair reballing preform which gives the user a QC tool to inspect that the reballed device and to simplify the rework if a single ball needed to be reworked.

1. Dress Site and Clean

1. Dress Site and Clean 2. Apply Paste Flux

2. Apply Paste Flux 3. Align and Place BGA on to Preform

3. Align and Place BGA on to Preform 4. Post Reflow and Preform Removal

4. Post Reflow and Preform Removal