PCB Bare Board ECO

Your BEST Source For High Quality ECOs and ECNs on Bare Boards

There are cases when you need a fast and/or extremely precise or very high volume bare board ECO (Engineering Change Order) or ECN (Engineering Change Notification) completed on an un-populated PCB. When these cases arise think of BEST as your “go to” source for getting you out of trouble when a board spin is not fast enough or there are tens of thousands of dollars in potential scrap that cannot be accepted.

Typical changes that BEST can perform on your board and are performed routinely include:

- Trace and conductor cuts

- Elimination of pads

- Addition of traces and pads

- Mechanical outline changes to a boar include the cutting of mounting holes

- Precise solder mask removal or additions

- Addition or removal of identification marks

Bare Board ECOs and ECNs - The BEST Solution

BEST has many years of bare board level engineering changes. We can import Gerber files to make sure that we can perform the exact modifications you want. Unlike other shops we have a plethora of different options including micro ablation, laser machining and in-house fabrication of traces and pads for high volume requirements. BEST engineers have been part of the IPCs’ 7721 PCB repair sub-committee which deals with the varies processes that are performed to the physical repair of PCBs. WE can perform these repairs on a variety of substrates including rigid, rigid/flex and flex substrates.

Below is a sampling of the kinds of repairs we can perform on your bare board:

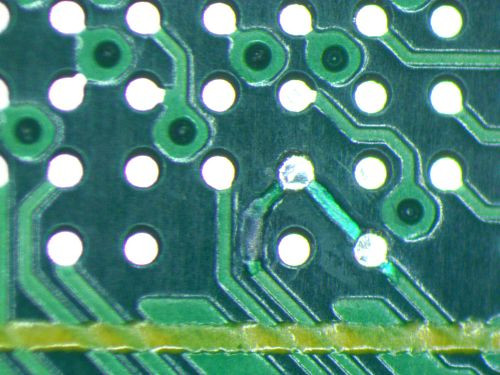

Trace Addition

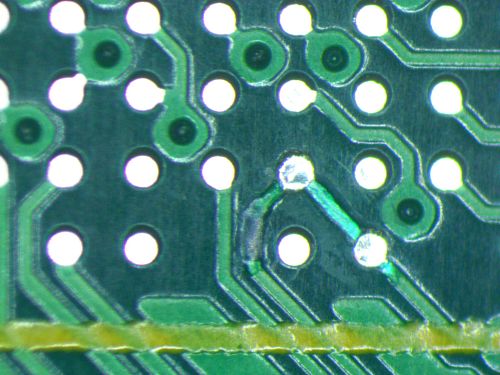

Trace Cuts

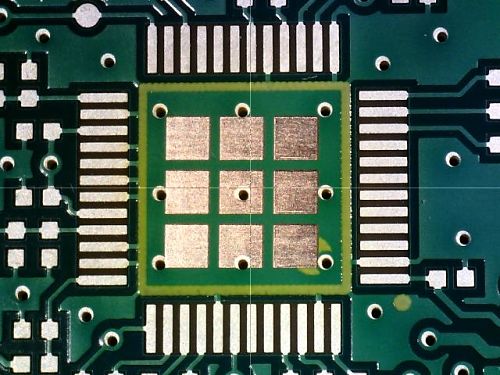

Soldermask ablation of ground pads on leadless device area

Call BEST today to see how we can help get you out of trouble!