X-RAY Sorting

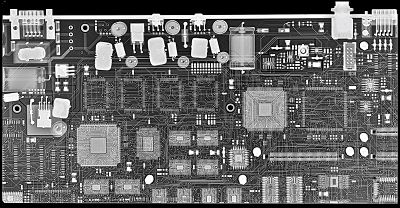

BEST has the equipment and expertise to provide electronic x-ray sorting and inspection of components, printed circuit boards, wire harnesses and other electronic assemblies.

Onsite at our Chicago area location are two high-powered (130kV) small 3um spot size x-ray systems which can resolve 2um features while handling printed circuit boards up to 711 x 762mm (28 x 30”). The systems feature articulating specimen tables which can be used to handle oblique / 3D viewing of component locations such as plated throughholes as well as POP assemblies. The systems are outfitted with sophisticated inspection software which have sophisticated software for hole fill calculations, ball sphericity calculations for BGAs, void detection calculations for leadless device ground connections amongst others. The machines can record videos of the assembly being inspected as well as being able to record high resolution images of defects or anomolies. The high plate voltages of the systems allow us to provide images of even the densest assemblies.

With the ability to capture clear images BEST trained personnel can sort through a variety of electronic assemblies. These include unpopulated printed circuit boards, flex and rigid flex assemblies which all be inspected per IPC-6102 or IPC-A-600 guidelines by certified instructors and associates. Assemblies which can be inspected per IPC-A-610 guidelines or by known “good” versus “defective” criteria. Furthermore cable assemblies including overmolded cables and connectors can be inspected per the latest IPC-A-620 criteria or by those inspection guidelines you set up. When it comes to are array devices such as BGAs, POPs, CCGAs and others BEST personnel have been rework and inspecting these component families as part of Class 2 and Class 3 assemblies for 20 plus years. We are well-versed in the IPC-7095 area array as well as the bottom termination IPC-7093 manufacturing guidelines and can advise on the inspection routines.

There are several ways in which BEST can deliver our electronic x-ray sorting services. In some cases we are asked to simply provide the inspection of the finished or unfinished raw assemblies or wire harness per the latest IPC inspection criteria documenting the results. Electronic x-ray inspection in some cases is part of this inspection process. BEST inspection technicians can deliver images and in some cases an inspection report. In pure electronic assembly sorting jobs we may provide inspection services in areas of the board with non visual soldering connection locations delivering x-ray images and documentation. For very large jobs where there is a suspect fault and production volumes may need to be sorted based on your provided acceptance and rejection criteria the assemblies may be divided out as “acceptable” and “rejected”.

BEST engineering may get involved on very large electronic x-ray sorting projects designing and assembling fixtures to speed up the sorting process. In these cases the device under inspection may be loaded into the fixture and the x-ray system will be programmed to “step and repeat” and capture the image while the trained x-ray technician makes the call.

Call BEST at 847-767-5745 or send your particular project request to info@solder.net.