Call us Now! 1-847-797-9250

BEST soldering geeks enable electronics companies to be more effective through professional instruction, tools and taking secondary assembly projects off your plate

BEST soldering geeks enable electronics companies to be more effective through professional instruction, tools and taking secondary assembly projects off your plate

Overview Benefits Instructions Void Reduction

Are you tired of the existing leadless device rework methods being in the hands of process experts due to the complexities and the dexterity required? Are you looking for a faster, more fool-proof leadless rework method? The new BEST StencilMate™ process is an answer to your QFN and LGA rework problems. This unique method simplifies the leadless device rework process allowing for better yields and faster rework times.

The simple nature of the StencilMate™ rework process allows even the beginning repair technician to reliably and quickly replace leadless device packages such as QFNs or LGA packages. Alignment is simple with the edges of the stencil being “squared up” with the sides of the package thereby eliminating the need to use custom fixtures or frames. The adhesive is engineered such that the it has enough “tack” to be held in place once you have aligned the stencil but not too much “tack” such that if you are misaligned it is impossible to start over. After the device has been reflowed, the stencil is simply peeled off and is ready to place.

The StencilMate ™ stencils are packaged and delivered to you the way you want. Stencils are custom made to your exact requirements without tooling charges. They are packaged such that those building PCB prototypes or removing and replacing leadless devices can use them.

These rework “bumping” stencils simplify the replacement of leadelss device packages such as LGAs, QFNs and others. StencilMate™ stencils are manufactured to your exacting specifications with the data taken from your device data sheet. The stencil is cut using a laser to your exacting device requirements. The stencil is aligned to the prepped device and reflowed. After reflow the stencil is simply peeled away and the device cleaned. Now this bumped device can be placed by other conventional means or aligned using the mating StencilMate™ stencil adhered to the PCB.

StencilMate™ stencils are packaged in groups of (20) in a small antistatic bag. Each packet also consists of enough stencils to “bump” (20) parts or or enough StencilMate™ device / board pairs to rework (10) devices. Squeegees are sold separately.

Download a brochure on StencilMate™ here

StencilMate™ Patent Pending, BEST Inc.

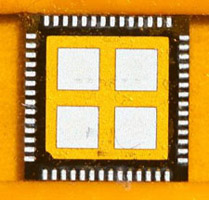

1. Align stencil to part.

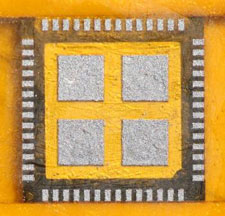

1. Align stencil to part. 2. Squeegee solder paste into aperatures

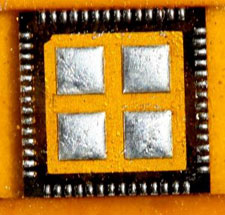

2. Squeegee solder paste into aperatures 3. Reflow. Remove StencilMate™

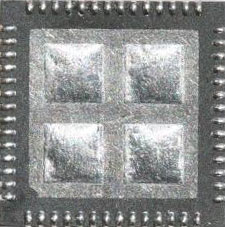

3. Reflow. Remove StencilMate™ 4. Clean and Inspect

4. Clean and Inspect