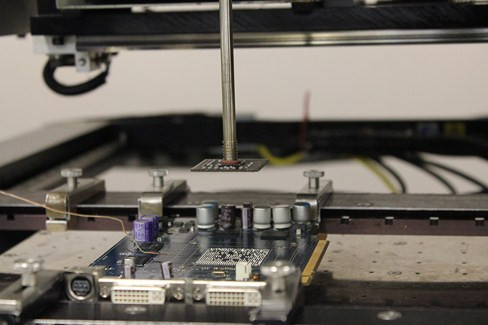

Medical Device Laser Machining

Lasers have been used to fabricate parts for the medical device industry for some time. The precision of the laser source, its small cutting “footprint” and its hygienically “clean” cutting aftereffects all make laser machining for medical device manufacturing of small-featured parts a favorite.

There are a myriad of different applications where laser machining has been used to cut or identify medical devices including but not limited to :

- Slitting catheter tubes

- Cold cutting of polymers that are lenses

- Cutting holes in high precision filter

- Microsurgical needle fabrication

- Cutting tight tolerances for implantable devices

- Guide wire machining

Laser machining of small parts using a laser in the medical device industry is used for a variety of reasons including but not limited to:

- Intricate parts manufacturing as the cutting beam can be steered in a very precise method

- Fast up time of new designs as no tooling has to be waited on

- High repeatability

- High material utilization rate as the cutting area is very small and parts can be nested more closely

In addition, the low aspect ratio (part minimum cutting dimension versus the material thickness) is low with laser machining of medical parts using a laser. Typically, this is in the 10:1 or better range.

Not only can BEST perform the machining of Kapton™ for cutting purposes but it can also provide for the laser marking of medical devices. Date codes, bar codes, serialization and part number generation are all areas where laser marking of materials like PEEK, Kapton™, Cirlex™ and others can be completed using BEST’s wide variety of laser sources.

In addition to pure laser machining services, let BEST be your partner in getting your new product off the ground. We can provide prototype to medium volume assembly services including testing, soldering, marking, packaging and fulfillment. Our production and engineering team can support your efforts to bring the product to market so you do not have to worry about the assembly and laser machining of medical devices.

BEST is ISO registered and has a robust quality control system including tools in place. We have a variety of digital metrology tools to make sure the parts we are producing meet the tolerances and specifications you have on the print.

BEST can accept a wide variety of file formats including GERBER, dxf, dwg or IGES or other 2D files.