Gold Finger Repair

Gold Fingers | BGA Pads | Plated holes | Edges | Mask | Populated Boards | Pad and Traces

Rework / Repair Services

Gold Finger PCB Repair Gold fingers are prone to damage as they are on the periphery of the circuit board and they are also prone to solder splash during the wave soldering process. When edge contacts are contaminated with solder, get scratched, torn or damaged, BEST repair technicians can bring them back into specification. These contacts can either be replaced or repaired. Our repair methods will restore your edge contacts to a high level of performance and reliability. BEST's highly skilled technicians can repair the gold fingers thereby eliminating the need to scrap the entire board. We have custom gold finger fabrication capabilities for those higher volume repair jobs in order to minimize the turn-around time and keep repair costs to a minimum.

Gold Finger PCB Repair Gold fingers are prone to damage as they are on the periphery of the circuit board and they are also prone to solder splash during the wave soldering process. When edge contacts are contaminated with solder, get scratched, torn or damaged, BEST repair technicians can bring them back into specification. These contacts can either be replaced or repaired. Our repair methods will restore your edge contacts to a high level of performance and reliability. BEST's highly skilled technicians can repair the gold fingers thereby eliminating the need to scrap the entire board. We have custom gold finger fabrication capabilities for those higher volume repair jobs in order to minimize the turn-around time and keep repair costs to a minimum.

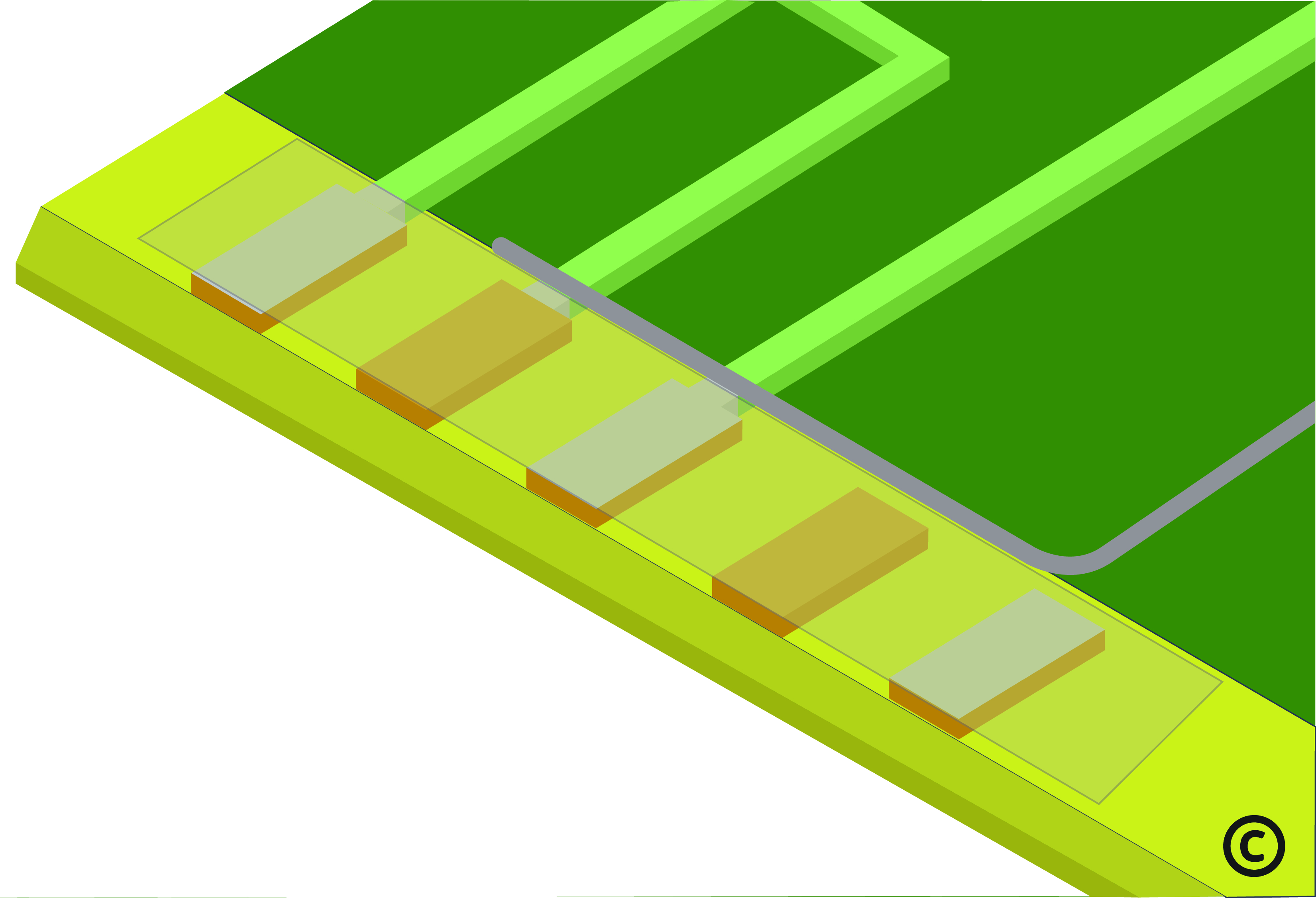

When the gold fingers get scratched, contaminated with solder or if the plating is worn they can be re-plated by BEST. The contaminated contacts are stripped down to the bare base metal and replaced to meet the thickness specified. BEST's electroplating process is reliable and will restore damaged contacts to "like new" condition with full functional conductivity and durability.

Scratched and Worn Gold Fingers Scratched and Worn Gold Fingers |

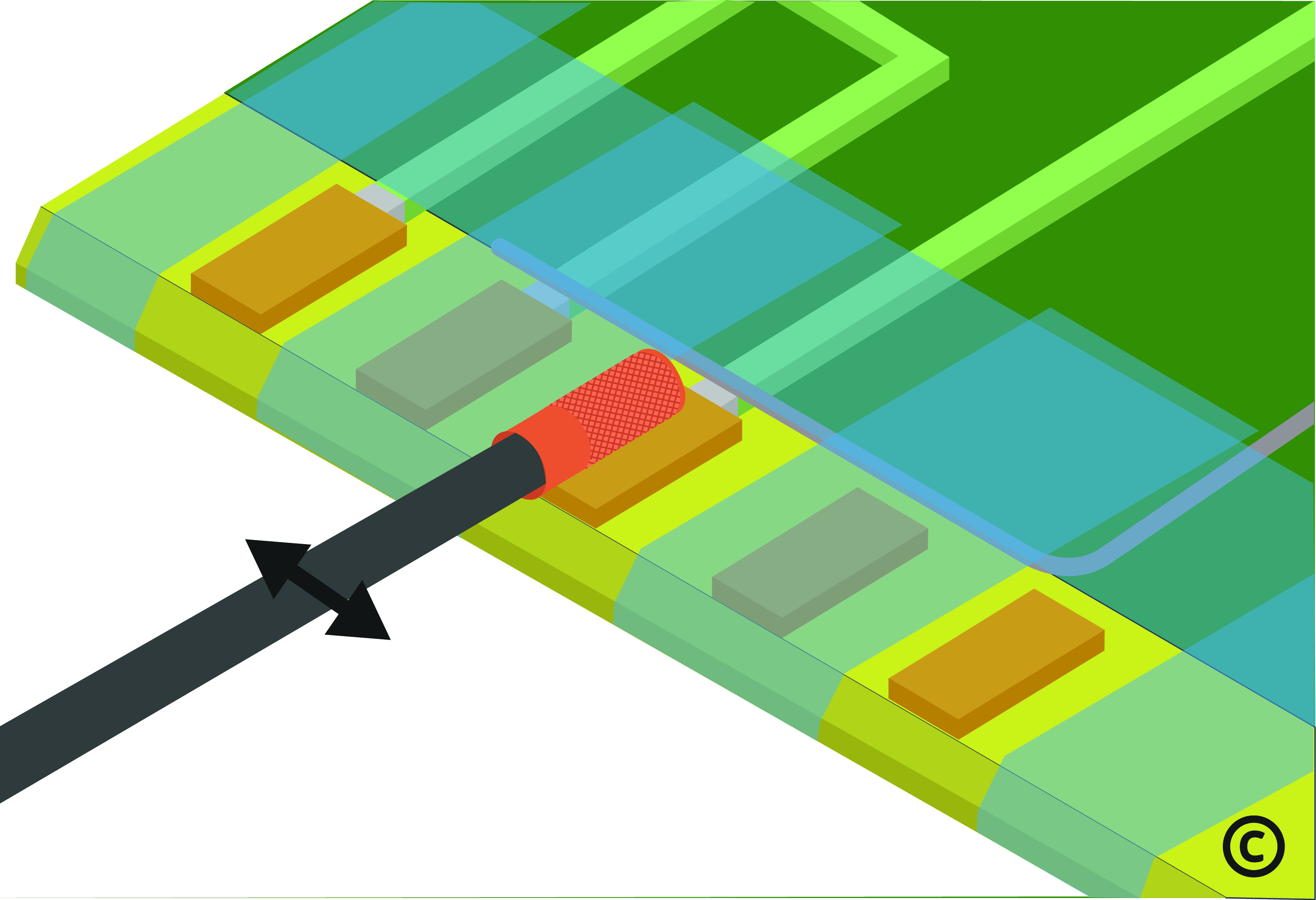

Goldfinger with Solder Goldfinger with Solder |

Goldfinger with Solder Goldfinger with Solder |

BEST Inc. can either :

1. Provide the training for you to perform your own replating process

2. Provide a complete gold contact replating kit including instructions and instructional videos

3. Provide a gold contact replating service

Generically for a replating process the first step is to clean and inspect the area to replated. At this point BEST will determine whether or not a replating process will be appropriate based on the extent of the damage or splash on the gold plated surface.

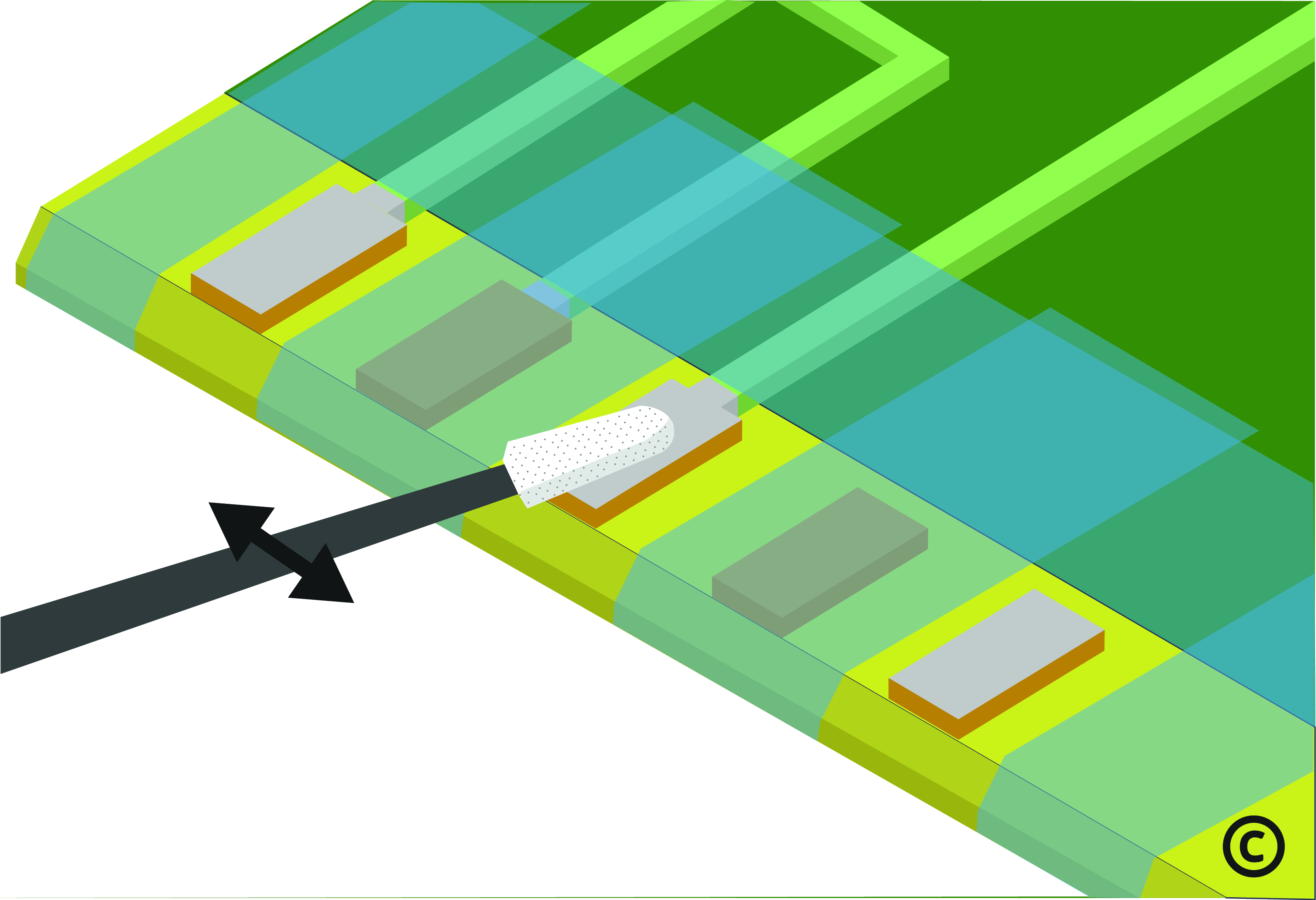

Areas in and around those with solder splash are taped off and the solder is wicked off and then a solution helps to strip off the remnant solder from the surfaces. If a replacement pad is required then a new gold plated pad is installed instead of spending time replating the existing pad.

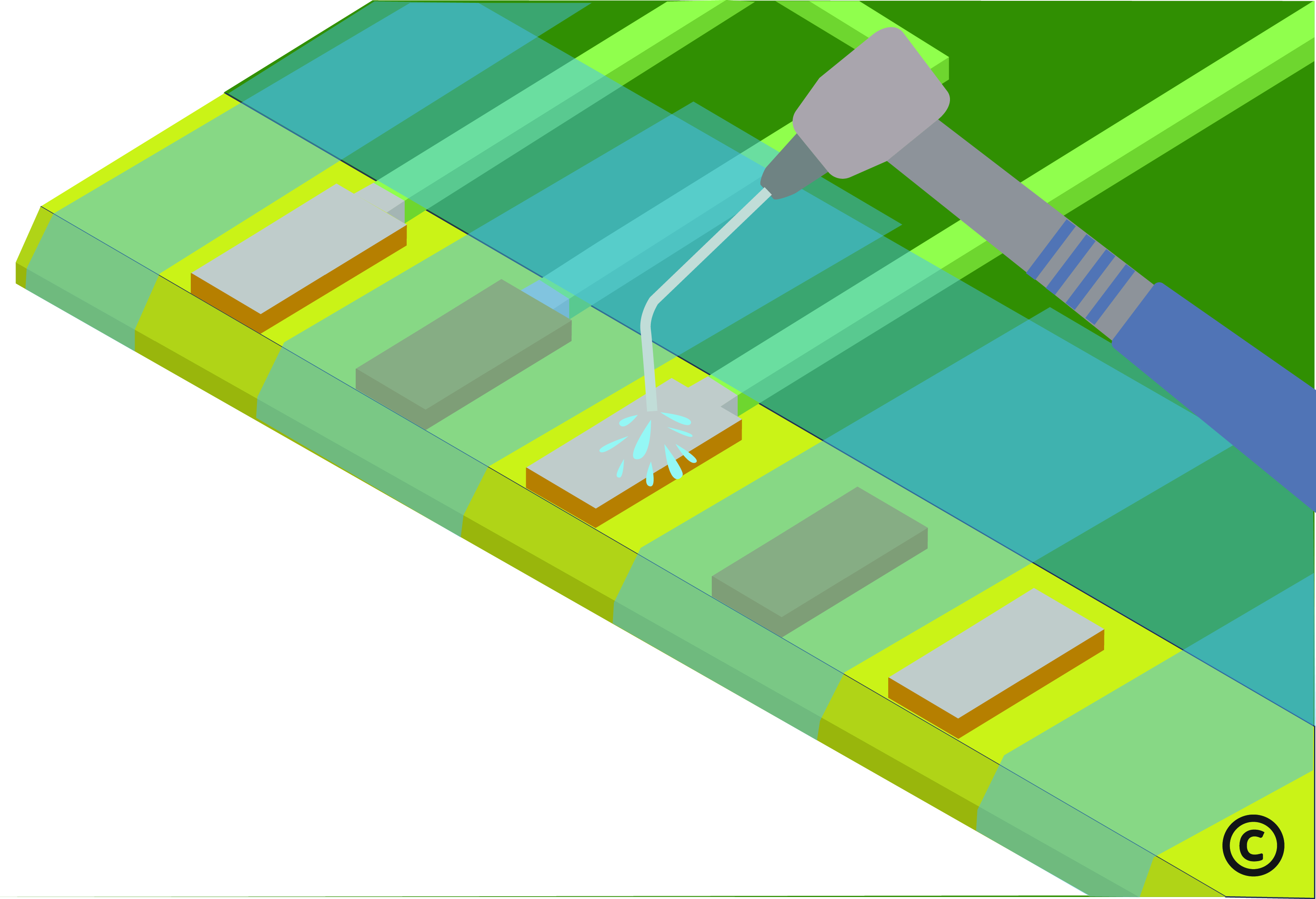

The solution remnants are then rinsed from the board. The board is then dried and inspected.

A bus wire is then attached in close proximity to the replating area. Using a small power supply with swabs connected to the electrodes the plating process is undergone using a nickel (if required) then gold plating solution. After plating the area is inspected and tested.