Call us Now! 1-847-797-9250

BEST soldering geeks enable electronics companies to be more effective through professional instruction, tools and taking secondary assembly projects off your plate

BEST soldering geeks enable electronics companies to be more effective through professional instruction, tools and taking secondary assembly projects off your plate

Successful rework and PCB assembly methods have been developed with lead-free solders for all types of components. During the transition period to lead-free manufacturing rework practices have to be developed that deal with the issues related to handling, reworking, tracking and inspecting lead free PCB assemblies.

Lead-free solder rework is different than Sn63 solders as the lead-free solder alloys typically do not wet or wick as easily. While SAC305 is the defacto "lead free" solder for rework BEST has experience with low melt temperature lead free solders and SN100X for the rework of throughole devices.

Successful rework methods have been developed with lead-free solders (including Sn/Ag/Cu or Sn/Ag alloys) including components removal/replacement,jumper wires, trace and pad repairs and BGAs. Most of your existing rework equipment for Sn63-based alloys can still be used for the lead-free solder. The soldering parameters must be adjusted to accommodate the higher melting temperature and lesser wettability of the lead-free solder. Studies have shown that reliable lead-free solder joints, with proper grain structures and intermetallic formation, can be produced using appropriate rework processes.

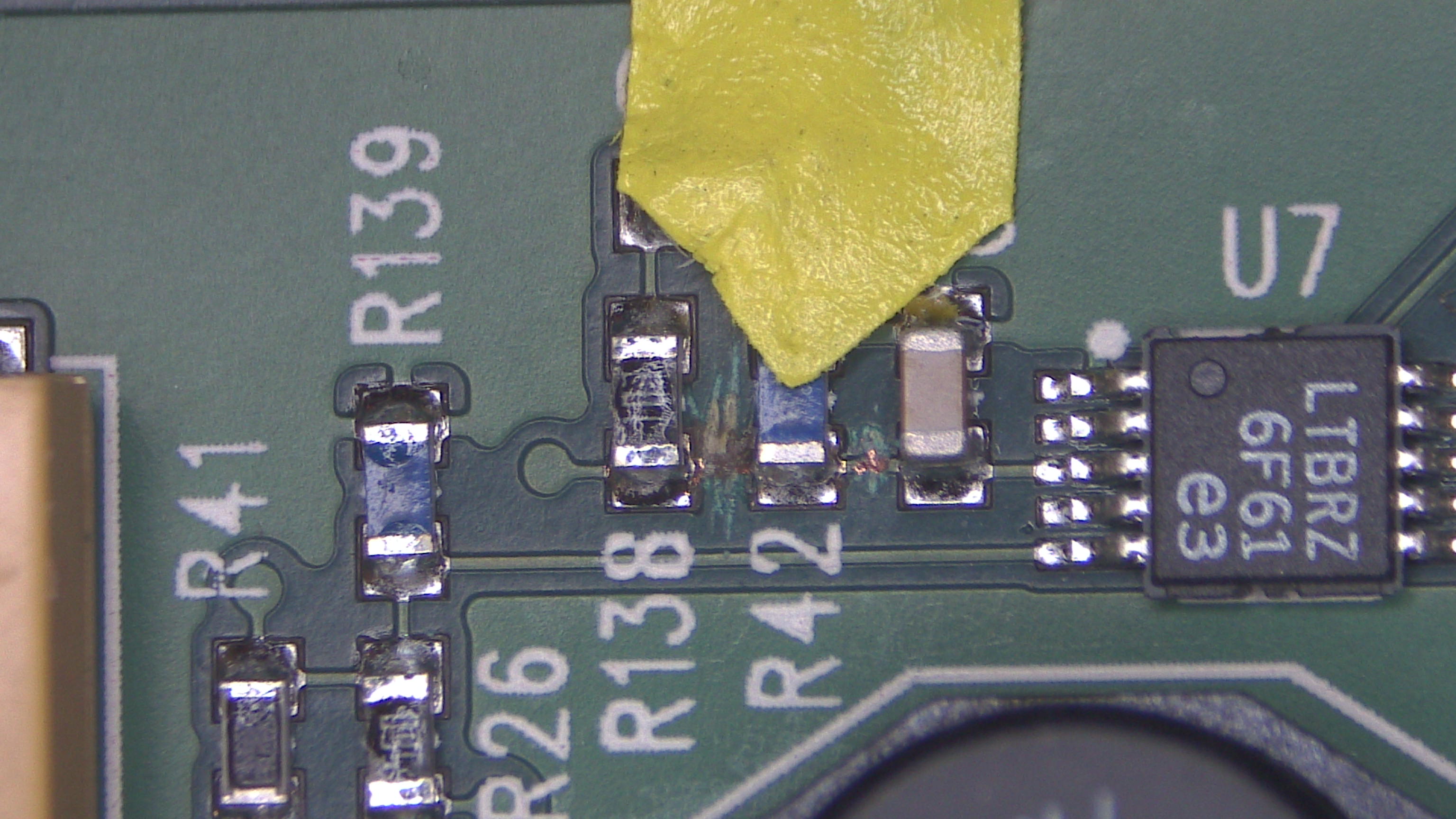

Example Gull Wing Lead Soldered Using SAC lead-free alloy

Example Gull Wing Lead Soldered Using SAC lead-free alloy

Care must be taken to minimize any potential negative impact of the rework process on the reliability of the solder interconnects, the components and the PCB. As the soldering temperature increases, the coefficient of thermal expansion (CTE) mismatch between the laminate material, the glass fiber and copper will exert greater stresses

on the copper, potentially causing failures by cracking of the copper traces or plated vias. The propensity of the rework operation to cause this cracking is a function of variables such as the PCB layer count and thickness, the laminate material, the rework temperature profile, the copper distribution, the via geometry as well as others. Alternative higher glass transition temperature, lower coefficient of thermal expansion laminate materials may need to be specified for lead-free soldering. Higher rework processing temperatures (approximately 30-40°C higher) may impact other components that are close to their melting or softening points such as connectors, batteries and labels.

The issue of "component mixing" warrants special concern, especially during the transition period. Preliminary studies on the impact of lead in lead-free solder on long-term reliability indicate that the impact varies with the amount of lead in the solder joint, and the impact may be the greatest when the amount of lead is within some intermediate range because of the formation of segregated phases (e.g., coarse lead grains) in the last-to-solidify interdendritic tin grain boundaries, where cracks may initiate and propagate under cyclic loading. For example, it has been shown that 2 to 5 percent lead can be detrimental to the fatigue life of lead-free solder, but it probably is no worse than the Sn63 solder. For example, if a PCB fabricated with Sn63 is to be repaired with lead-free solder, from the solder point of view, the reliability of mixed lead-free solder and Sn/Pb solder will likely not be inferior to the Sn63 solder. However, the temperature impact on the components would be a concern. On the other hand, repairing a lead-free soldered board with Sn63 solder would create solder joints that are not as reliable as the lead-free solder joints on the rest of the board.

In terms of logistics, during the transition period it is key that solder irons and materials (wire core solder, flux gels, etc.) for lead-free soldering be clearly labeled. Reviewing the JEDEC lead free PCB assembly and component identification guidelines will be required in order to properly mark and identify the materials. Operators must be trained in lead-free rework processes and most importantly inspection. A good review of the IPC A 610-D revision will be in required as part of this training.