Overview

Printed Circuit Board Rework Services Eliminate Rol Mdws

Reality

PCB rework will always be a part of our lives. We see it in the form of engineering change orders, product upgrades and revisions, general automated process errors, etc. Rework is one of the most unpredictable and variable parts of the PCB assembly process. In fact, no other single function in the assembly process negatively affects profitability more than rework.

Experience

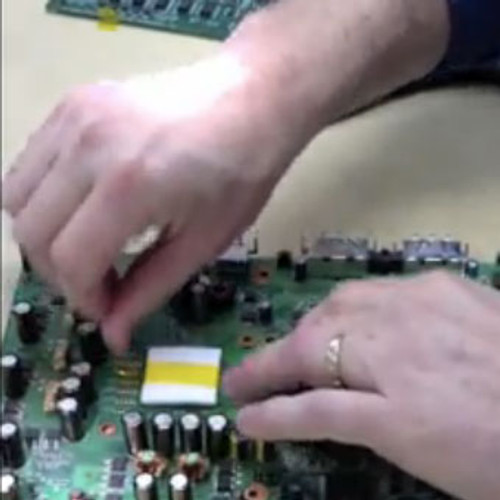

Solder Rework & Repair Services Our Contract Rework/Repair Division has the ability to provide expert rework, repair, and ECO modifications to your PCBs, as well as prototype runs. Our state of the art equipment and IPC certified operators insure the work done on your PCBs will be done quickly, correctly and reliably. 100% guaranteed. BEST has performed printed circuit board rework services for projects ranging from 1 board to 175,000 boards, and guarantees that 100% of your boards will be returned to you without damage. We have saved our customers millions of dollars by assisting them with the rework/repair process and providing fast, reliable service. Because of our specialized processes in rework and repair, our operators' output per person far exceeds that of in-house operators. Compare your fully burdened overhead rate of rework/repair to our per board price - you'll be surprised.

Solder Rework & Repair Services Our Contract Rework/Repair Division has the ability to provide expert rework, repair, and ECO modifications to your PCBs, as well as prototype runs. Our state of the art equipment and IPC certified operators insure the work done on your PCBs will be done quickly, correctly and reliably. 100% guaranteed. BEST has performed printed circuit board rework services for projects ranging from 1 board to 175,000 boards, and guarantees that 100% of your boards will be returned to you without damage. We have saved our customers millions of dollars by assisting them with the rework/repair process and providing fast, reliable service. Because of our specialized processes in rework and repair, our operators' output per person far exceeds that of in-house operators. Compare your fully burdened overhead rate of rework/repair to our per board price - you'll be surprised.

Examples of Rework performed:

|

Examples of PCB Repair performed:

|

Staff

Our rework & repair associates are experienced professionals with a minimum of 5 years of rework/repair experience. Not only are they certified to IPC-A-610, IPC 7711/7721 and J-STD-001 standards, they also receive specific application training on a day-to-day basis from our IPC Certified Master Instructors. We are confident in our staff and their ability to manage your most demanding projects.

Quality

BEST has made an investment in the most advanced and versatile rework/repair equipment currently available. We only use equipment which allows for strict process control, and each solder joint is inspected by the operator and QA technician. All rework and repair is performed in accordance with IPC-7711/7721, guidelines for Rework, Repair, and Modification of Printed Circuit Boards and Electronic Assemblies. All boards are inspected in accordance with IPC-A-610, Acceptability of Electronic Assemblies.

Commitment

After we have performed your rework project, our service does not end there! BEST, in conjunction with one of our largest customers, has developed the theory of Rework Management & Optimization. In summary, Rework Management and Optimization involves implementing the correct mix of Equipment, Training and Outsourcing to maximize your internal resources. Your current process is analyzed and a framework is provided to increase productivity, decrease scrap/damage, quickly move WIP to final goods, and dramatically reduce the overall cost of doing rework. BEST will help you implement this process and assist if needed.