Call us Now! 1-847-797-9250

BEST soldering geeks enable electronics companies to be more effective through professional instruction, tools and taking secondary assembly projects off your plate

BEST soldering geeks enable electronics companies to be more effective through professional instruction, tools and taking secondary assembly projects off your plate

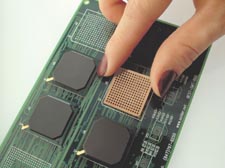

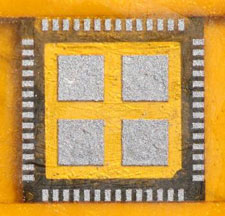

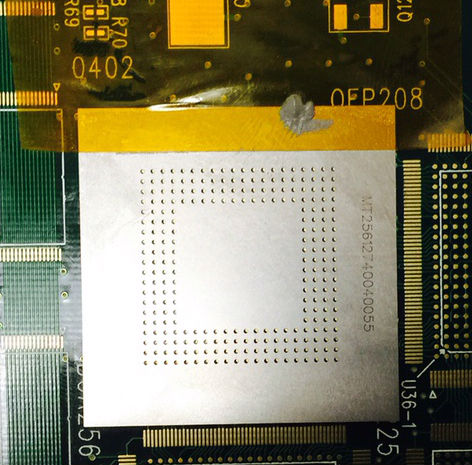

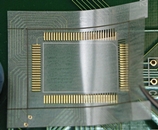

Adhesive-backed single use rework stencil prevents solder from squirting underneath the stencil thereby eliminating multiple reworks. Allows for squeegeeing into tight spaces as it is made from flexible mylar film with repositionable adhesive allowing you to print more easily on heavily-populated boards. This simplifies the rework printing process as multiple passes insure proper fill of apertures and a more consistent print volume.